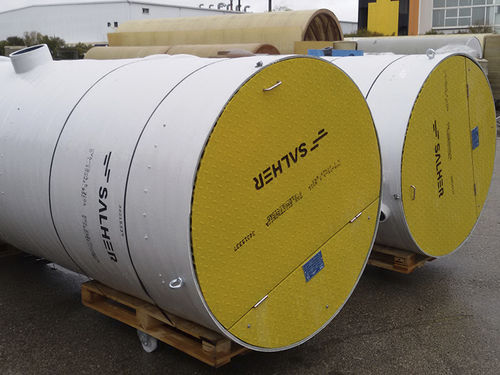

Wastewater pumping station

Add to favorites

Compare this product

Characteristics

- Applications

- wastewater

Description

These equipment are composed of an outer GFRP structure (glass fiber reinforced polyester), with inlet and impulsion pipes and outlets for cables and ventilation.

In addition, these pumping stations are equipped with a GFRP or metallic electrical panel board with one or more contactors up to 5.5 hp, thermal relays, star-delta starters from 7.5 hp (inclusive), start/stop indicator lamps, manual or automatic selectors, fuses, automatic rotation (for 2 pumps), optical/acoustic alarm for high level.

Optionally, we can supply voltmeter, ammeter and hour counter, hoist for pump extraction, cast-iron covers, stairs, systems of deodorization and cleaning of the pumping station, self-cleaning bottom, fixing brackets in case of high water table, covers for pedestrian crossing and safety systems against falling.

Its inner part includes the assembly of pipes, 90º curve, elbows, etc., manufactured according to the EN 12050-1 Standard.

Inside the following is included:

– submersible pumps (vortex, single-channel or multichannel impeller) with automatic anchoring and descent devices;

– level measurement systems through level regulators or ultrasounds;

– and check valves for fecal water and valves of elastic closing gate with mounting in pumping station or in independent valve vault.

In addition to the equipment presented, our Technical Department develops customized pumping stations to satisfy most of the wastewater pumping requests that include optional elements such as:

Technical platforms in the tank, to improve the safety of the maintenance operator.

Automatic screening systems.

Stairs with guardrails.

Catalogs

No catalogs are available for this product.

See all of Salher‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.