- Machine-tools

- Cutting Tool

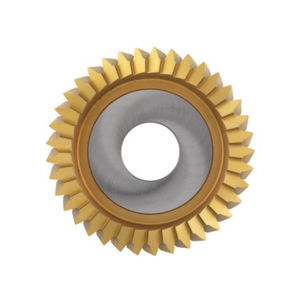

- Cutting tool

- SAMPUTENSILI

Cutting tool

Add to favorites

Compare this product

Description

In collaboration with the world’s leading manufacturers of tool coating technology, we optimize innovative coatings for gear cutting tools to improve abrasion resistance, wear resistance and consequently tool life.

Automated cleaning equipment further optimizes the coating process. Substrates are delivered for coating in a thoroughly clean state to help guarantee the ultimate quality of the coated product. In-house coating units are integrated in Samputensili manufacturing sites all over the world and are frequently updated with the latest process technology. This close co-operation means that any new developments in anti-wear coatings are made available to you immediately.

Nowadays, the new development in the tool coating industry is represented by the new coating ALTENSA by Oerlikon Balzers which represents the latest innovation in the coating market. Its characteristics enable to apply high speeds, obtaining huge productivity gains, time savings and cost efficiency.

The main ALTENSA advantages are:

Reduced machining cost

Reduced wear at high speed

Longer tool life

Significant improvement for highest cutting speed conditions for all substrate materials

Increased productivity

This new coating is ideal for markets which need high cutting speed such as automotive. It is recommended in the hobbing, shaping and scudding® processes.

Main advantages:

Best coating on the market

Wide range of coating in order to satisfy clients’ needs

Better tools performance, thereby more productivity

Catalogs

No catalogs are available for this product.

See all of SAMPUTENSILI‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.