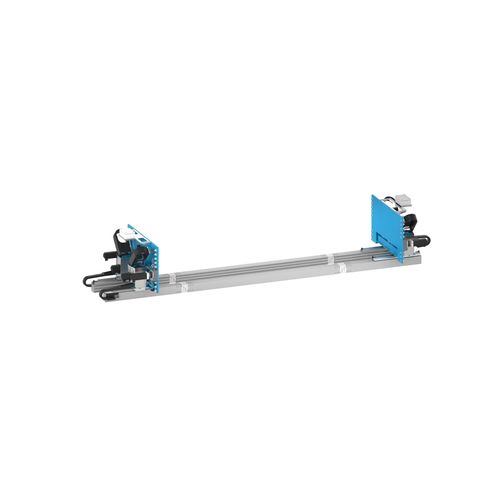

Press transfer system NGT series transportfor sheet metalfor grippers

Add to favorites

Compare this product

Characteristics

- Product applications

- for presses, transport, for sheet metal, for grippers

- Type

- automated, tool positioning, programmable

- Capacity

100 kg, 200 kg

(220.5 lb, 440.9 lb)

Description

The new NGT transfer systems are based on the well-known quality and feature the functionalities of the Sander transfer systems.

This of course includes a control system, which ensures that the transfer system runs 100% synchronously with the press at all times.The NGT systems are designed for 2D and 3D operation for medium & high volume production.

High transport quality, free programmability of all movements, vibration compensation and central lubrication are examples of the product’s standard.A dashboard which visualizes performance and maintenance data at a glance is accessible via the touch screen control.

The component selection and design are deliberately aimed at minimizing maintenance costs.In addition, we offer our well-known 24-hour spare parts service, which ensures high availability of the systems.Predictive maintenance strategies are supported via OPC/UA interface.

The scope of delivery includes an up to 45-stage parts sensing, which can be expanded with additional functions.A freely programmable virtual cam controller offers up to 32 inputs/outputs to control sensors and drives.

Last but not least, all NGT systems come with throughput optimization software.This tool determines the throughput-optimized interaction of press, die and transfer during the design phase.This software also provides the motion data to enable virtual commissioning on the basis of digital twins.

VIDEO

Catalogs

Other Sander Automation products

Sheet Metal Forming TRANSFER SYSTEMS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.