- Machine-tools

- Cutting Tool

- Face parting and grooving tool

- Sandvik Coromant

- Products

- Catalogs

- News & Trends

- Exhibitions

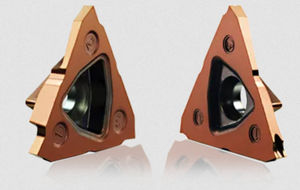

Face parting and grooving tool CoroCut® QDexternalinsertwith internal coolant

Add to favorites

Compare this product

Characteristics

- Type

- external, face

- Features

- insert

- Other characteristics

- steel, with internal coolant, modular

Description

Over- and under coolant system cools the cutting zone for better chip control, extended tool life and higher cutting data. Easy coolant connection with plug and play adaptors.

Geometries designed for good chip formation, high stability and coolant access in combination with grades that provide excellent edge-line security in all materials makes for inserts that excel in every parting off operation.

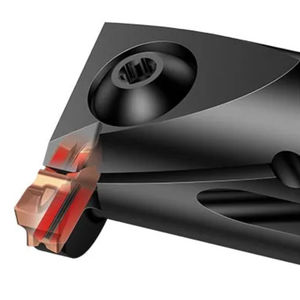

CoroCut® QD, for Y-axis parting, is designed with the insert pocket rotated 90 degrees, providing more than six times higher blade stiffness in turning centres and multi-task machines with Y-axis.

First choice for parting off Diameter: 38–160 mm (1.5–6.3 inch)Cutting widths (CW): 1.0–8.0 mm (0.04–0.315 inch)

Deep grooves Cutting depth (CDX): 15–80 mm (0.6–3.15 inch)Cutting widths (CW): 2.0–8.0 mm (0.08–0.31 inch)

Machine types: Turning centres, sliding head machines, multi-spindle machines

Y-axis parting: turning re-invented

Get to know Y-axis parting – a completely new way of parting off. While conventional parting off uses feed motion along the X-axis with the cutting force directed through the weakest section of the blade, CoroCut® QD for Y-axis parting is designed with the top face of the insert perpendicular to the blade. This gives a more beneficial direction of the cutting force, resulting in considerably higher stability and reduced vibration.

CoroCut® QD for Y-axis parting is first choice for parting off in turning centres, multi-task machines and sliding head machines with Y-axis. It can machine large diameters, up to 180 mm (7 inch), and is particularly suitable for long overhangs to reach between main- and sub-chuck.

VIDEO

Catalogs

Small part machining

58 Pages

Related Searches

- Sandvik Coromant milling cutter

- Drilling tool

- Steel milling tool

- Clamping milling cutter

- Solid drilling tool

- Metal milling tool

- Milling tool with cylindrical shank

- Sandvik Coromant insert milling cutter

- Cast iron milling tool

- General purpose drill bit

- Cutting milling tool

- Face milling tool

- Roughing milling tool

- Shell-end milling tool

- Carbide drilling tool

- High-performance milling tool

- Shoulder milling tool

- Stainless steel milling tool

- 2-flute milling tool

- Twist drilling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.