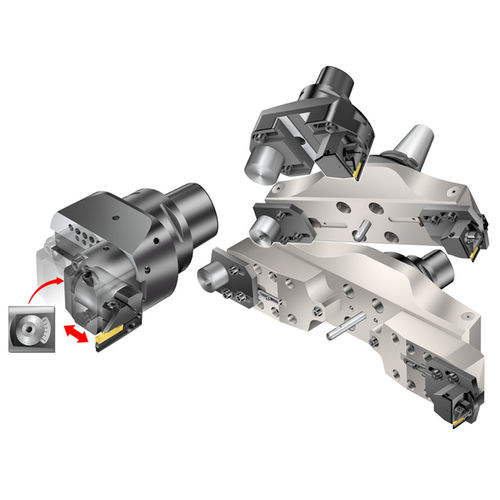

Machining grooves with CoroBore® SL is a productive alternative to milling grooves. This fine-adjustable axial face grooving tool machines grooves in a large number of components and diameters.

Benefits

Increased productivity compared to milling

Excellent chip control thanks to internal coolant to the cutting edge

Builds on our large assortment of standard SL32 blades and CoroCut system 1-2 inserts

Radial fine-adjustable face grooving heads for pre-setting

Features

Rigid design with dedicated tools for small and large diameter face grooving

Internal coolant

Radial fine-adjustable face grooving head for pre-setting

For smaller diameters: 47–150 mm (1.850–5.905 inch), C6 and C8 adaptors available

For larger diameters: 150–1275 mm (5.905–50.20 inch), use a dedicated face grooving head with CoroBore XL

Application

Recommended starting value for feed: 0.15 mm/rev (0.006 in/rev)

Typical application: pump and valves, hydraulic components and pulp & paper.

First choice geometries: -CM or -TF depending on chosen nose radius

If grooves with larger width tolerance is required, chose -GF geometry