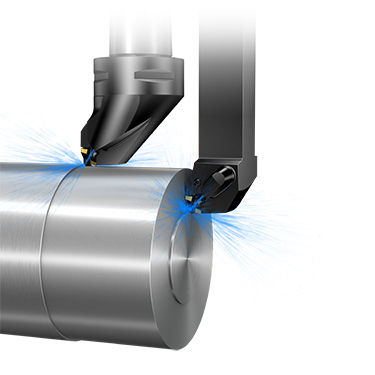

Chip control and long and predictable tool life

High precision coolant from above controls the chip breaking for secure machining, while under coolant controls the temperature for long and predictable tool life. The coolant also have positive effects on surface quality.

High-quality surfaces

To achieve the highest quality of surfaces, the key is to prevent cutting forces from causing micro-movements of the insert. iLock®, an interface between insert and holder, is developed to bridge this challenge.

Easy tool change for maximized production time

Coromant Capto® interface or QS™ shanks enable quick tool change and easy coolant connection for maximized production time.

External operations

Longitudinal and face turning

Finishing to medium

Machine types: turning centres and multi-task machines

Eight-edged smartness

The eight-edged inserts of CoroTurn® 300 ensure good heat transformation for predictable performance and wear. More edges also means fewer inserts which in turn means better control of the inventory. The geometries are designed for excellent chip breaking within their respective application areas. Last but not least; the eight-edged insert design means less carbide per edge which means less material to recycle and waste. Good for you and for the environment.