- Machine-tools

- Cutting Tool

- Face grooving tool

- Sandvik Coromant

- Products

- Catalogs

- News & Trends

- Exhibitions

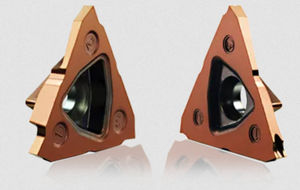

Face grooving tool CoroCut® QFinsertsteel

Add to favorites

Compare this product

Characteristics

- Type

- face

- Features

- insert

- Other characteristics

- steel

Description

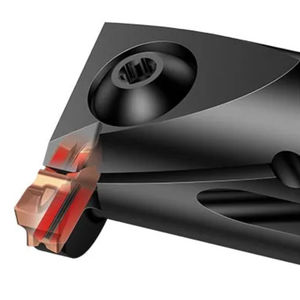

More material in the weakest cross-section and decreased mass in the front part of the blade provide higher dynamic stiffness, effectively reducing vibration. The slit is optimized to provide correct clamping force.

Tilted insert with stabilizing rails at the top, bottom and back of the insert to minimize insert movement.

Improves chip evacuation and decreases the risk for chip jamming, critical factors for successful deep face grooving operations. Effective from low to high coolant pressures.

Face grooving

Minimum first cut diameter (DAXIN): 30 mm (1.18 inch)

Maximum cutting depth (CDX): 50 mm (1.97 inch)

Minimum corner radius: 0.2 mm (0.008 inch)

Tool selection

There are a number of important aspects to consider when choosing the right face grooving tool for your operation, such as clockwise or counter clockwise spindle rotation, A- or B-curve and right- or left hand tool. Use the step-by-step guide to facilitate your tool selection

VIDEO

Catalogs

No catalogs are available for this product.

See all of Sandvik Coromant‘s catalogsRelated Searches

- Sandvik Coromant milling cutter

- Drilling tool

- Steel milling tool

- Clamping milling cutter

- Solid drilling tool

- Metal milling tool

- Milling tool with cylindrical shank

- Sandvik Coromant insert milling cutter

- Cast iron milling tool

- General purpose drill bit

- Cutting milling tool

- Face milling tool

- Carbide drilling tool

- Roughing milling tool

- Shell-end milling tool

- High-performance milling tool

- Shoulder milling tool

- Stainless steel milling tool

- 2-flute milling tool

- Twist drilling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.