- Building - Construction

- Construction and Mining Equipment

- Continuous miner

- Sandvik Mining and Rock Technology

- Products

- Catalogs

- News & Trends

- Exhibitions

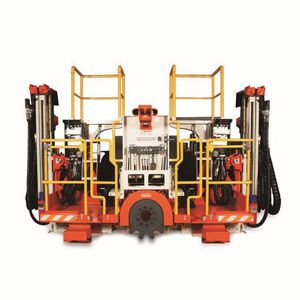

Continuous miner with roof bolter MF320

Add to favorites

Compare this product

Characteristics

- Options

- with roof bolter

Description

Sandvik MF320 is a crawler-mounted borer miner designed to drive entries and headings and mine rooms as fast as haulage equipment can remove material to the main haulage. This full-face machine is specially engineered to cut and deliver material to the rear of the machine in a single continuous operation. It is an ideal choice for potash, trona, and salt mining.

Advantages

Long-lasting components for low cost of ownership and more uptime

Operates with high availability, resulting in low maintenance costs

Radio remote control available for better visibility and flexibility

On-board Sandvik roof bolting rigs ensure safe operation

Technical data

Dimension (L-W-H) - 12,400 x 5,100 x 3,150 mm

Cutting width - min 4,800 / max 5,100 mm

Cutting height - min 2,840 / max 3,150 mm

Profile area - 15 m2

Machine weight - ~160 t

Total installed power - 990 kW

Electric supply voltage - 3300 V /50 Hz

Due to more than 4 decades of experienced designing and manufacturing, Sandvik's MF320 Borer Miner is capable of cutting and delivering materials to its rear end in one non-stop operation. The boring-type, crawler-mounted full-face constant mining machine sports either a barrel-shaped or top drum cylindrical design, single-sided main control orientation, and on-board Sandvik roof bolting rigs. A top cutter drum, a proportionate load sensing hydraulic system, and a track lock mechanism are also part of the MF320 Borer Miner's primary set of features.

Rounding out the Sandvik MF320 Borer Miner's overall features are optional degasification drills, an optional remote control for the device, and an optional data recording system.

Catalogs

No catalogs are available for this product.

See all of Sandvik Mining and Rock Technology‘s catalogsOther Sandvik Mining and Rock Technology products

MECHANICAL CUTTING EQUIPMENT

Related Searches

- Sandvik drilling rig

- Sandvik rotary drilling rig

- Sandvik mobile drilling rig

- Sandvik hydraulic drilling rig

- Sandvik crawler drilling rig

- Multifunction drilling unit

- Sandvik civil engineering drilling rig

- Sandvik construction drilling rig

- Sandvik core drilling drilling rig

- Diesel engine drilling rig

- Dump truck

- Combustion engine dump truck

- Core bit

- Down-the-hole drilling rig

- Water well drilling rig

- Exploration drilling unit

- Deep drilling rig

- Diesel dump truck

- Horizontal drilling rig

- DTH hammer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.