- Hydraulics - Pneumatics

- Filter and Separator

- Wastewater filter

- Sanin Filtertechnik GmbH

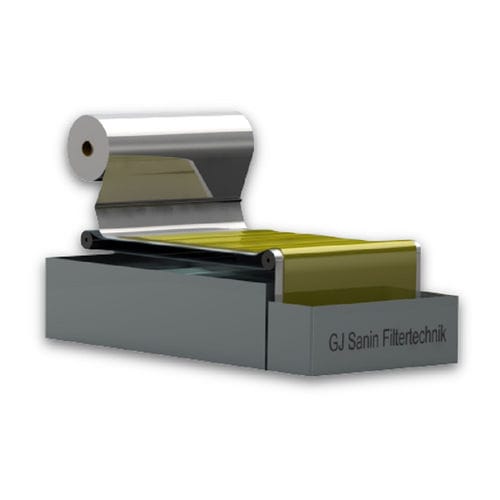

Belt filter wateroilfor wastewater

Add to favorites

Compare this product

Characteristics

- Designed for

- water, oil, for wastewater

- Filtration element

- belt

- Filtration method

- gravity

- Applications

- industrial, process, for chemical applications, for machine tools, for purifying, for water treatment, for grinding machines, automotive

- Fluid specification

- for coolant, lubricating oil, process water

- Other characteristics

- automatic, high-throughput

Description

Belt filter systems are very versatile and are used in the chemical industry, in pharmacy, the food industry and environmental engineering. They are furthermore ideally suited for the separation of solids from liquids in the manufacturing process of paints and pigments, in the mineral industry as well as in mining and metalworking. The filter media are either continuous filter belts made of different plastic/stainless steel fabrics or filter nonwovens as rolled goods. The filter medium can be arranged horizontally,

inclined or semicircular. Belt filters in basic designs work with gravity. More complex versions can also work with overpressure or reduced pressure/vacuum. There are very small belt filters with filter surfaces of less than one square meter as well as variants with more than 250 m². Best filtration performances are achieved in applications with a solids content of 3 to 40 % at particle sizes between 1 and 100 µm. Here is a short overview of the different variants with filter fleece and filter nonwoven recommendations.

Gravity belt filters are the easiest and cheapest version of industrially used belt filter systems. They are easy to operate and, because of their low mechanical requirements for the nonwovens, flexible in regard to their selection. Despite their fully automated function they are very robust and due to low acquisition costs and low-maintenance construction, they are cost-efficient for many applications. Because only small water columns with low pressure can form, the filter nonwovens are not ideally used. Resulting in a large space requirement we recommend them mainly for water-based applications.

Catalogs

No catalogs are available for this product.

See all of Sanin Filtertechnik GmbH‘s catalogsRelated Searches

- Liquid separator filter

- Filter cartridge

- Industrial filter cartridge

- Pressure separator filter

- Filter for industrial applications

- Fine filter cartridge

- Filter housing

- Water separator filter

- General purpose filter cartridge

- Water filter cartridge

- Cartridge filter housing

- Liquid filter housing

- Polymer filter cartridge

- Panel pre-filter

- Filter element

- Compact separator filter

- Metal filter housing

- Process separator filter

- Stainless steel filter housing

- Pleated filter cartridge

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.