- Industrial machines and equipment

- Welding and Assembly

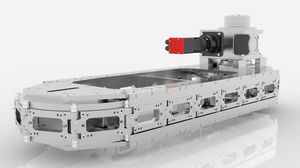

- Automatic assembly machine

- Sankyo Automation, Inc.

- Products

- Catalogs

- News & Trends

- Exhibitions

Automatic assembly machine BH seriesfor industrial applicationscustompick-and-place

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Applications

- for industrial applications

- Other characteristics

- custom, precision, pick-and-place

Description

0~12 pick & place handler

6~36 indexing station

Synced motion

BH Series rotary assembly machine features an indexing dial plate with synchronized pick & place, or pressing handlers mounted above the indexing dial plate. Driven with one motor, up to 12 pick & place and/or pressing handlers can mount in any combination or angular position around the bull gear drive. For accurate positioning at high speeds with a small footprint, this is the ultimate assembly machine. Just add finger tooling, station fixtures and power.

• Rotary assemble requiring 6 to 36 stations

• Assembly requiring 10 input, 2 unload stations (inspection, measuring, crimping)

• Replace short conveyor applications with smaller footprint

• Synchronized linear & rotary with line shaft drive withup to 90 cycles/minute

• Linear torque limiter for each pick & place handler

• Rotary torque liming clutch for rotary indexing dial plate

• Rotary encoder for motion timing

• Variable speed motor controller (VFD)

• Servo motor drives for frequent on demand cycling

• Custom base plate & frame configurations

• Dual assembly machines in a common form with rotary transfer handlers between dial plates

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.