Battery high low temperature test chamber is designed to test all types of batteries, including lithium-ion batteries. The battery test chamber has many safety functions built into the test chamber, which can handle battery tests and prevent safety accidents.

Charge/discharge cycle testing, which determines the number of times a battery can be used by evaluating it until it deteriorates after repeated cycles of charging and discharging.

In the laboratories involved in battery testing, tests based on charge and discharge cycles are a key activity. The instruments used for this type of test usually perform harsh and lengthy test protocols on the battery and can usually be connected to various instruments.

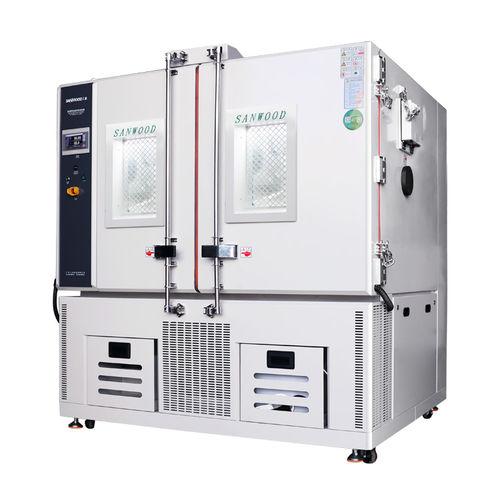

Battery High Low Temperature Test Chamber Structure and Characteristics:

1. Battery Temperature Explosion-proof Test Chamber composed of the chamber, refrigeration systems, heating systems, air circulation system and control system.

2. Battery Temperature Explosion-proof Test Chamber is made of high quality SUS#304 stainless steel material,the outer shell adopts A3 steel plate,surface electrostatic spraying.

3.Insulation system uses superfine fiberglass wool or polyurethane foam so as to ensure the temperature of inside chamber.

4.Temperature and humidity control adopts Korean import TEMI360 programmable touch screen temperature and humidity controller, with automatic calculation of PID function.

5.Adopts steam humidifying method, automatic water circulation loop,with functions of automatic filling water.

6.Refrigeration system adopts original France "Taikang" refrigeration unit and full sets of refrigeration parts.

7.Input mode PT100 sensor.