- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

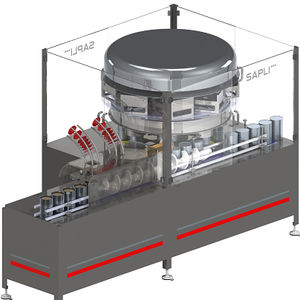

Automatic can seaming machine VGS-3with vacuum technology

Add to favorites

Compare this product

Characteristics

- Type

- automatic

- Options

- with vacuum technology

Description

MULTI STATION VACUUM GASSING AND SEAMING

Sapli’s Vacuum Gassing and Seaming stations can be configured with or without vacuum-gassing option (adding of inert gas in vacuum chamber). The Customer chooses:

•atmospheric

•vacuum

•vacuum and gassing seaming operations machine.

The vacuum-gassing option is needed depending on the

product requirements. More than one station machine is

applied in low and medium production speeds, depending on

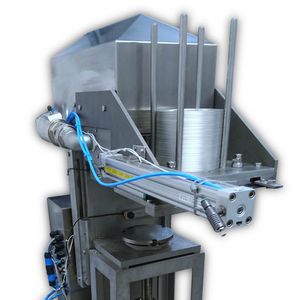

the product requirements. Sapli offers the unique on the market highly-efficient cans feeding system, developed specially for maximum reduction of vacuum gassing and sealing cycle and achieving of the optimal level of Oxygen.

Technical Features:

•The multi head machine is high performance solution for medium production speeds.

•The modular principle allows adding new seaming stations in the future, in case of increasing of production capacities.

•Suitable for the seaming and vacuum gassing products in tinplate, aluminium, paperboard and plastic cans packaging across a wide range of industrial sectors.

•Perfect sealing technology with adjustable working speeds.

•Easy and intuitive format change.

•Adjustable levels of residual O2 level after seaming, depending on the product requirements for guaranteeing a long shelf-life of the product.

•Vacuum and gassing pressures are configurable, and can be monitored on each can seaming cycle

•Suitable for the wide range of tin cans formats, heights and diameters.

•Multiformat principle allows working with lots of packaging formats at the same machine.

•Food grade grease lubrication and seaming rolls that do not require lubrication

Catalogs

No catalogs are available for this product.

See all of Sapli‘s catalogsRelated Searches

- Automatic filler

- Liquid filler

- Automatic labelling machine

- Feeder

- Filler for the food industry

- Bottle filler

- Food product filling machine

- Palletizer

- Bottle labeling machine

- Volumetric filler

- Semi-automatic filler

- Multi-head filler

- Side labelling machine

- Filler for the pharmaceutical industry

- Sealer

- Automated feeder

- Labeling machine for the food industry

- Labeller for the pharmaceutical industry

- Complete packaging line

- Automatic palletizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.