- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

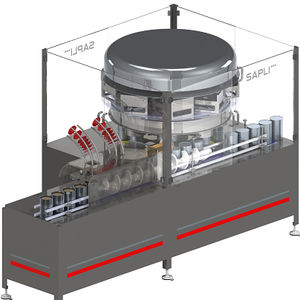

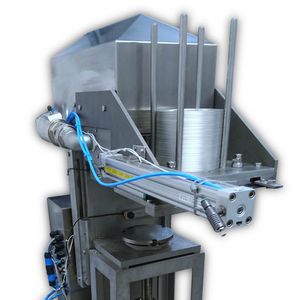

Semi-automatic can seaming machine VGS SEMI-AUTO SEAMER 7 UPMwith vacuum technologywith gas injection system

Add to favorites

Compare this product

Characteristics

- Type

- semi-automatic

- Options

- with vacuum technology, with gas injection system

Description

Semi-Auto Seamer with vacuum and gas injection system.

Equipment extracts the air (oxygen) from the can and in between the particles of the product. This space is refilled with Nitrogen or any other gas or gas mix required to add quality to the final product. Before can is taken back to the line it is seamed, and it all happens in the same point. No need of extra equipment.

The machine can be configured to work in 3 different modes:

a) - sealed mode only (up to 14 u/min)

b) - sealed mode + air extraction

c) - sealed mode + air extraction + inert gas gassing (up to 7 u/min)

Depending on the packaged product, the process may be different but it allows the user to exchange different productions in the same equipment. This equipment is designed for low speed or semi-automatic lines of up to 7 units per minute in full mode sealing + vacuum + gas.

If it goes to sealed mode only, production speed is increased up to 14 units per minute (always in automatic feeding mode, in manual mode it depends on the speed of operation of the person).

The equipment reduces the oxygen level inside the can to the assigned value (normally below 1-2%).

Features

✓ Production: 7 units per minute (14upm without gassing)

✓ Ready for can different diameters and heights

✓ Under 0.5% Oxygen inside

✓ N2, CO2+N2, Ar etc

✓ Multiple products inside

✓ Metal, cardboard, aluminium, plastic cans

✓ Low and high production speeds adaptable.

✓ Seam with or without modified atmosphere.

✓ Upgradable machine to higher speeds

Catalogs

No catalogs are available for this product.

See all of Sapli‘s catalogsRelated Searches

- Automatic filler

- Liquid filler

- Automatic labelling machine

- Feeder

- Filler for the food industry

- Bottle filler

- Food product filling machine

- Palletizer

- Bottle labeling machine

- Volumetric filler

- Semi-automatic filler

- Multi-head filler

- Side labelling machine

- Filler for the pharmaceutical industry

- Sealer

- Automated feeder

- Labeling machine for the food industry

- Labeller for the pharmaceutical industry

- Complete packaging line

- Automatic palletizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.