- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

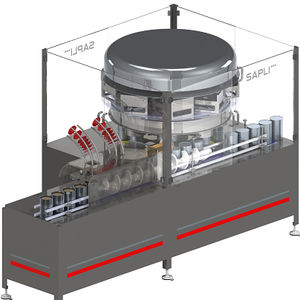

Can seaming machine with vacuum technology VGSX SEAMER 21UPMwith gas injection system

Add to favorites

Compare this product

Characteristics

- Options

- with vacuum technology, with gas injection system

Description

Seamer with vacuum and gas injection system.

Features

✓ Production: 21 units per minute (42upm without gassing)

✓ Ready for different can diameters and heights

✓ Under 0.5% Oxygen inside

✓ Round, square and irregular shape cans

✓ N2, CO2+N2, Ar...

✓ Multiple products inside

✓ Metal, cardboard, aluminium, plastic cans

✓ Low and high production speeds adaptable.

✓ Seam with or without modified atmosphere.

✓ Upgradable machine to higher speeds

SOLUTION

Vacuum gassing is needed in multiple products such as milk powder, baby infant formula, coffee, snacks, crisps or peanuts depending on their requirements. Equipment is applied in high speeds production and automatic lines. Sapli offers the unique on the market highly-efficient cans seaming system, developed specially for maximum reduction of vacuum gassing and sealing cycle and achieving of the optimal level of Oxygen.

Method (In-line system):

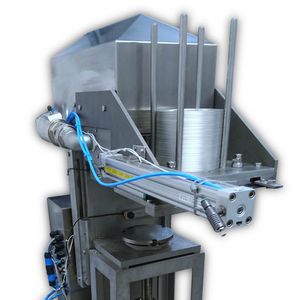

1. Cans are fed into the Sapli machine via a screw dividing product.

2. Each can is individually and hermetically closed and the process of vacuum-gassing begins (air is evacuated and nitrogen is added according to an individual formula for each product).

3. The can and end are clamped onto the stationary seaming chuck, and the double seaming operation is initiated.

4. After seaming, the closed can is gently taken into the transportation conveyor

Catalogs

No catalogs are available for this product.

See all of Sapli‘s catalogsRelated Searches

- Automatic filler

- Liquid filler

- Automatic labelling machine

- Feeder

- Filler for the food industry

- Bottle filler

- Food product filling machine

- Palletizer

- Bottle labeling machine

- Volumetric filler

- Semi-automatic filler

- Multi-head filler

- Side labelling machine

- Filler for the pharmaceutical industry

- Sealer

- Automated feeder

- Labeling machine for the food industry

- Labeller for the pharmaceutical industry

- Complete packaging line

- Automatic palletizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.