- Products

- Catalogs

- News & Trends

- Exhibitions

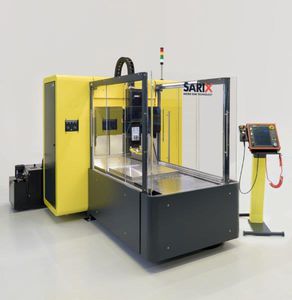

3-axis machining center SX200 DUAL PULSARverticalmillinghigh-productivity

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Associated functions

- milling

- Other characteristics

- high-productivity, high-precision, for micro-machining, EDM

- Rotational speed

60,000 rpm

(376,991 rad.min-1)

Description

The versatility of the SX-200 Dual machine brings now new innovative possibilities on the 3D high precision Micro Machining.

The capabilities of the combination of the high speed end mill milling gives now the advantages of an effective machining time reduction.

Micro end mill used up to 60’000 rpm associated to the milling machining strategies of the SX-3D Milling CAM software prepares the fine roughing of the work piece.

The same Milling CAM software execute the finishing of the work piece with the SARIX module SX-3D Micro EDM Milling CAM through efficient machining electrode wear compensation and Micro EDM strategies.

The additional automatic electrode wear compensation and electrode re-feeding rotating spindle associated with the indexing function (C) and the electrode shaping on the Wire EDM device(SX-Arianne) opens up new opportunities of size and form electrode for a full continuous “One setup” machining process.

Micro EDMing machining technology with solid carbide electrode from 45 Microns to 3.0 mm.

Micro EDM Milling of Micro forms and Micro structure down to 20 Microns.

Micro EDM Milling high surface finishing down to Ra 0.1with the SX-MFPS Micro Fine Pulse Shape generator.

Catalogs

No catalogs are available for this product.

See all of SARIX‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- Drilling machine

- Milling CNC machining center

- High-productivity CNC machining center

- Drilling CNC machining center

- CNC drilling machine

- High-speed CNC machining center

- Vertical drilling machine

- High-speed drilling machine

- Compact drilling machine

- Micro-machining CNC machining center

- EDM drilling machine

- Laser CNC machining center

- Deep hole drilling machine

- Micro-drilling machine

- CNC micro-drilling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.