Measurement control system BSMCfor billetsautomatic

Add to favorites

Compare this product

Characteristics

- Function

- measurement

- Product applications

- for billets

- Other characteristics

- automatic

Description

One of the main commercial targets of SARRALLE EQUIPOS SIDERÚRGICOS is to meet our Customer needs, especially when the finished product quality is involved.

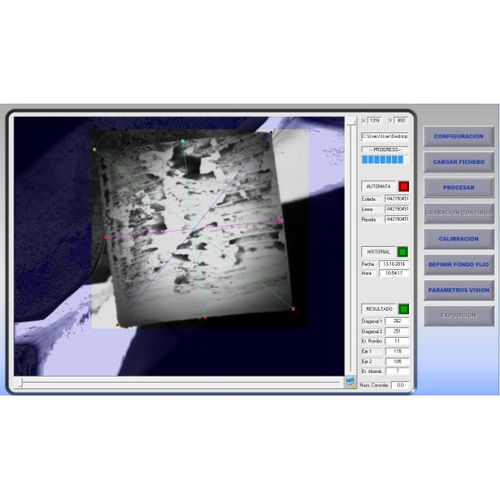

In this context, SARRALLE has recently developed a Billet Section Measuring & Control System (BSMC) in collaboration with TAUCON, a new strategic partner specialized in Artificial Vision Technology.

The BSMC System has been conceived to automatically measure main dimensions of billet sections produced at Continuous Casting Machine and to transfer the information to the operator in control room in real time.

The main advantage of this installation is to collect measurement and detect at the same time any irregular parameter in billet dimensioning.

To guarantee BSMC proper functioning, it is highly recommended to install SARRALLE Deburring Machine.

NEW DEBURRING MACHINE

The in-line rotary milling cutter type Deburring Machine is designed to remove burrs from continuous casting products (billet and bloom) caused by torch cutting. The deburring process is executed during transportation on roller table without stopping the product and allows a neat product head and tail cleaning.

BENEFITS

Low running and maintenance costs

Fully automatic operation

Reversible cutting blades

Minimization of billet repetitive impact fatigue thanks to shock absorber system

Essential for Billet Section Measuring & Control System (BSMC) proper functioning

Minimization of damage/wear to rolling mill equipment

Catalogs

No catalogs are available for this product.

See all of SARRALLE‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.