- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

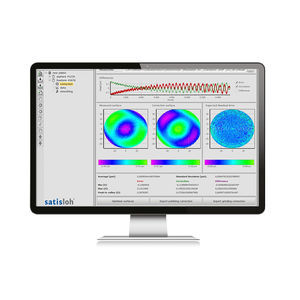

Monitoring software MES-360 POprocess controlmanufacturing execution systemprocess

Add to favorites

Compare this product

Characteristics

- Function

- monitoring, process control, manufacturing execution system

- Applications

- process, machine

- Type

- real-time, open platform

Description

Satisloh’s modular open platform Manufacturing Execution System MES-360 PO automatically collects, tracks, and shows all machine and process data. It enables the user to analyze and draw conclusions, and as a result, to implement improvement actions in order to increase overall equipment effectiveness.

MES-360 PO for Smart Manufacturing

In the manufacturing process of precision optics components a vast amount of data is being generated and processed. Some of this data is evaluated manually but a lot is neither recorded nor analyzed, although useful for process control and thus the improvement of quality and production effectiveness.

Satisloh’s MES-360 PO enables users to track and monitor process and machine data in order to save time and money by increasing the overall equipment effectiveness and maximizing quality and yield.

MES-360 PO is an open platform system seamlessly connectable to both Satisloh’s and other manufacturers’ machines. It also interfaces with most LMS and ERP systems.

Modular system: step-by-step implementation as user requirements evolve

Data can be viewed simultaneously by multiple people and on different devices

Machine Monitoring:

This MES-360 PO module improves machine uptime and efficiency by optimizing throughput times, and enables immediate troubleshooting in case of machines being down.

Features:

Machine status data

Productivity reports with machine utilization details

Cycle time tracking for each machine

Error/alarm tracking

Tool usage tracking

Tool change and maintenance prompts

Dashboard showing real-time machine status and jobs

E-mail/SMS alerts in case of machine errors

Catalogs

No catalogs are available for this product.

See all of Satisloh‘s catalogsRelated Searches

- Management software solution

- Process software solution

- Windows software solution

- Computer-aided design software

- Online software

- Real-time software solution

- Design software solution

- Monitoring software solution

- Measurement software

- Interface software

- Quality software

- Simulation software

- Network software solution

- Machine software

- Optimization software solution

- Calculation software

- Server software solution

- Internet-based software

- Laboratory software

- Process control software solution

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.