- Products

- 2D barcode verifier

- SATO America

2D barcode verifier CLNX™1D

Add to favorites

Compare this product

Characteristics

- Options

- 2D, 1D

Description

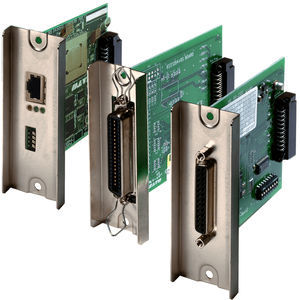

SATO’s Barcode Validator for the CLNX Series printer allows users to automatically scan and validate all 1D and 2D barcode symbologies on their printed label. It supports all printer resident barcodes or those imaged as a graphic, such as printing a PDF via Windows-based printer driver.

The Barcode Validator provides integrated operation with the CL4NX/CL6NX printer models which can be configured to either read and/or compare barcode data. Easy to use and implement with no additional software required, as operational settings are selectable directly from CLNX LCD menu.

Overview

The Barcode Validator has an overstrike feature to retract and void the label if the barcode data does not scan properly, preventing poor quality labels from being applied and used in the supply chain. Upon error, it can be configured to automatically reprint the label or stop printer operation, thus reducing label waste. For customers who are under compliance mandates, the Barcode Validator has a built-in logging feature which provides an audit of the labels printed for quality checking. The log file can also be uploaded to a host system for archiving purposes. The SATO Barcode Validator solution enhances efficiency of your label printing and provides quality assurance that can ultimately lower your labeling costs.

Barcode Validator Key Features:

• Checks the readability and data of the printed 1D or 2D barcodes

• Simple to configure and integrated printer operation with SATO CLNX series printer models

• Retracts and voids over labels if barcode data cannot be validated

Barcode Validator Key Benefits:

• Prevent unreadable barcodes from being applied and entering the supply chain

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.