- Production Machines

- Textile machinery

- Ring spinning machine

- SAURER SCHLAFHORST

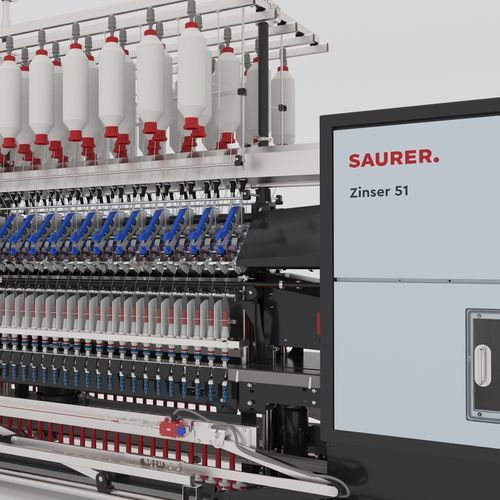

Ring spinning machine Zinser 51compact

Add to favorites

Compare this product

Characteristics

- Type

- compact, ring

Description

Zinser 51 is offered as a ring-spinning or as a compact-spinning machine. It sets new standards for sustainable spinning, maximum economy, optimised user-friendliness, and flexible automation solutions in ring spinning.

E³: our development philosophy

The needs of our customers are our top priority. With every new or further development, we pay attention to reducing energy consumption, increasing efficiency and improving ergonomics. The E³ philosophy underlies all our designs and our smart solutions provide added value to customers. With the transformation of the textile industry for the Circular Economy, the processing of sustainable fibres is another important focus point in our developments.

• Powerful and electronic drafting drive technology

• Low friction tangential drive combined with Eshape spindles

• Low energy consumption thanks to Twinsuction and Optisuction

• Innovative self-cleaning compact waste chamber

• Energy monitoring for maximum cost transparency

• Consistent yarn quality thanks to NF²D middle drive

• Considerably reduced maintenance cost due to innovative systems

• Maximum productivity for commodity and special applications

• Full range of applications with Spinnfinity

• Roughly 13% more productivity per m²

• Higher production thanks to self-cleaning compact technology

• Flexible adaptation of Easyspin with remote access

• Maintenance free drafting drive

• Hands free spindle brake application

• Made-to-measure automation

VIDEO

Catalogs

Zinser 51

24 Pages

Related Searches

- Winding machine

- Automatic winding machine

- Yarn winding machine

- Spinning machine

- Carding machine

- Automatic spinning machine

- Bale opener

- Compact spinning machine

- Automatic bale opener

- Ring spinning machine

- Rotor spinning machine

- Bale opener for the textile industry

- Cotton carding machine

- High-speed spinning machine

- Natural fiber carding machine

- Worsted yarn spinning machine

- Synthetic fiber carding machine

- Polyester spinning machine

- Semi-automatic spinning machine

- Air-jet spinning machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.