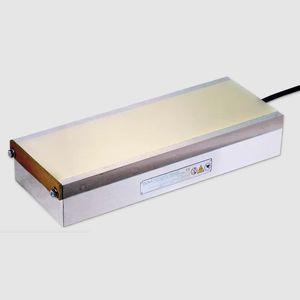

Electro-permanent magnetic chuck SAV 243.72rectangularfor grinding

Add to favorites

Compare this product

Characteristics

- Technology

- electro-permanent

- Type

- rectangular

- Applications

- for grinding

Description

Electro permanent magnetic chucks with fine longitudinal pole pitch P = 4 mm and magnetisable stop bars

The newly developed workholding system allows workpieces to be reliably pulled against the stop using magnetisable stops. Insertion errors can be prevented with this, particularly in shift operation. Electro permanent magnetic systems with very narrow pole pitch. The magnetic force is generated by the permanent magnets which are magnetised and demagnetised with short current pulses. Especially suitable for thin parts.

Primarily for precise grinding of mass-produced parts, especially in shift operation. For toolmaking, the system allows precision machining to the µm relative to the reference edge against the stop.

Magnetically active stops automatically

controlled in sequence

For thin workpieces up to:

min. thickness = 12 mm

(depending on stop height)

For flat workpieces:

min. width = 40 mm

Design with 2 strong bipolar systems for the stop bar, for reliable alignment of the parts. The stop magnet works at a time offset to the base magnet

The stop bars are magnetised before the main chucking area. This reliably pulls the workpiece into the lower corner of the stop.

Pole plate with particularly narrow, continuous longitudinal pole pitch, 3 mm steel and 1 mm brass

Pole divisions bonded and additionally bolted together solidly with tie rods

High accuracy thanks to pole plates bolted in a narrow grid

Switch-off using demagnetising cycle

8 mm wear layer on the pole plate

Low magnetic field height of 4 mm

Electro-permanent magnetic system for absolute safety in case of power failure

Chucking slots on both face sides

Catalogs

SAV 243.72

2 Pages

Related Searches

- Magnetic chuck

- Grinding magnetic chuck

- Rectangular magnetic chuck

- Electro-permanent magnetic chuck

- Permanent magnet magnetic chuck

- Machine tool magnetic chuck

- Milling magnetic chuck

- Turning magnetic chuck

- Sine table magnetic chuck

- Circular magnetic chuck

- Manual magnetic chuck

- Large part magnetic chuck

- Square magnetic chuck

- Magnetic block

- Radial magnetic chuck

- Permanent magnetic block

- Switchable magnetic block

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.