Drum screen VSAscrewfor wastewater treatmentfine

Add to favorites

Compare this product

Characteristics

- Type

- drum, screw

- Applications

- for wastewater treatment, fine

Description

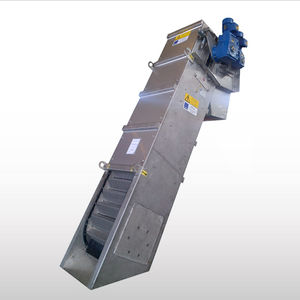

SPIRAMATIC VSA Fine Drum Screens are used in both municipal and industrial applications, as well as for the pretreatment in MBR plants. The machine screens, washes, conveys, and dewaters screenings all in one unit, thus eliminating the need for multiple pieces of equipment.

Description

SPIRAMATIC VSA Fine Drum Screens consist of a rotating drum screen, a conveyor screw, and a compaction zone. Depending on the application, the fine screen drum can be made up of a set of steel bars – in which case the distance between the bars determines the desired slot width – or of a perforated sheet filter. The cylindrically shaped drum can be placed inside a channel or a fabricated tank.

Function

SPIRAMATIC VSA Fine Drum Screens wash, convey and dewater waste water screenings all in one unit. They are designed to wash out organic matter from screenings. Both screen basket and dewatering zone are self-cleaning. Rotating around its axis, the cylindrical filter conveys the screenings to a loading hopper placed in the centre. A set of spray nozzles washes the filter during operation. A screw, placed inside the conveying pipe, with its top in the discharge hopper, conveys the screenings towards the following treatment stages during which organic substances are washed out. Subsequently, solids are compacted and dewatered in the compacting and drainage area. Finally, solids are discharged through an discharge chute into a container or compactor.

Catalogs

Related Searches

- Solid classifier

- Centrifugal classifier

- Classifier for the recycling industry

- Screen

- Cyclone classifier

- Bar screen

- Sand classifier

- Thickener

- Sludge treatment thickener

- Clarifier

- Fine screen

- Drum screen

- Screw screen

- Circular separator

- Radial clarifier

- Coarse screening screen

- Belt screen

- Clarifier with scraper bridge

- Processing workstation

- Grit separator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.