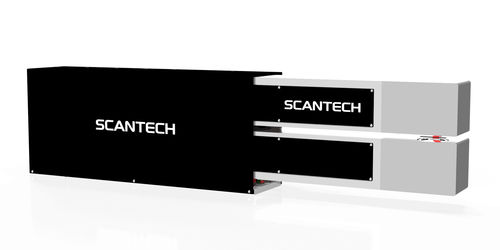

The µ C 3 scanner series has been designed to be extremely compact. Nevertheless, their maintenance is amazingly easy. Thanks to a wide range of sensors, they can be used in numerous types of applications.

• ANODE AND CATHODE

• CAST FILMS

• BLOWN FILM LINE

• BATTERY SEPARATOR FILMS

• ALUMINUM FOIL

• COPPER LEAVES

• CERAMIC FOIL

• PREPREG

BENEFITS

ROBUSTNESS

Extremely sturdy Structure

This design offers excellent resistance to torsion and bending of the frame and guarantees greater stability over time.

In standard, the frame and lids are made of anti-corrosion treated steel and painted in light grey (RAL 7035).

EMBEDDED SYSTEM

Integrated WEB Server System

The scanner has an integrated WEB server system, combining all the maintenance tools, allowing you to perform maintenance using web browser on any of the following media: PC, MAC, tablet or Smartphone.

SSA3 system

The Micro C 3 scanners are all equipped with the IoT (Internet of things) to enable them to connect with any hardware and give them a very long life, without obsolescence.

IoT and data analytics offer new opportunities every day to control and improve your production processes safely.

FAST OPTIMIZATION

Just 2 hours to setup

Add a new system to your production line in a record time.

Just 2 hours machine downtime to parameterize all of our measurement technology within a production.

EASY ACCESS FOR MAINTENANCE

Maintenance is done on 1 side

The Micro C 3 scanners have been designed to provide simplicity and fast maintenance operations. For this, all electrical, electronic and mechanical elements have been placed on the same side of the Scanner (maintenance side).