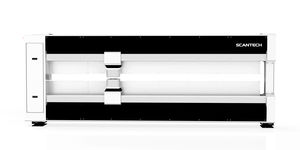

1D scanner HF3 measurementX-raycompact

Add to favorites

Compare this product

Characteristics

- Number of axes

- 1D

- Applications

- measurement

- Technology

- X-ray

- Configuration

- compact

- Length

Max.: 10,500 mm

(413 in)Min.: 4,000 mm

(157 in)

Description

The HF3 scanner series has been designed to be very solid, for high ambient temperature and very large web width. Nevertheless, their maintenance is amazingly easy. Thanks to a wide range of sensors, they can be used in numerous types of applications.

• BIAX LINES

• CAST FILMS

• PLASTIC SHEETS

• NONWOVENS

• TEXTILES

• PREPREG

• COATING LINES

• LAMINATION LINES

• LIQUID PACKAGING LINES

• ALUMINUM FOIL

• COPPER LEAVES

ROBUSTNESS

Extremely sturdy Structure

This design offers excellent resistance to torsion and bending of the frame and guarantees greater stability over time.

In standard, the frame and lids are made of anti-corrosion treated steel and painted in light grey (RAL 7035).

AIR CIRCULATION

Prevent deformation

The scanner is equipped with a ventilator which ensures that the complete frame is floated with a stabile air temperature. This prevent deformations in the frame.

RELIABILITY AT ALL EVENTS

Suitable for hazardous environments

Our devices offer incredible durability in your demanding manufacturing environments: fiberglass, carbon fiber and non-woven.

Extreme conditions: high humidity, high temperature, dusty environment.

THICK MATERIAL

Extended measuring gap

This type of scanner allows to have a measuring gap up to 150mm.

EASY ACCESS FOR MAINTENANCE

Maintenance is done on 1 side

The HF 3 scanners have been designed to provide simplicity and fast maintenance operations. For this, all electrical, electronic and mechanical elements have been placed on the same side of the Scanner (maintenace side). This allows a simpler maintenance on a compact production line.

Catalogs

Extrusion measurement system

16 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.