- Products

- Catalogs

- News & Trends

- Exhibitions

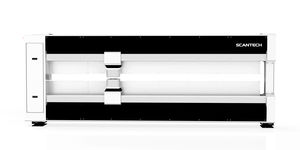

1-axis scanner C-FRAMEmeasurementX-raycompact

Add to favorites

Compare this product

Characteristics

- Number of axes

- 1-axis

- Applications

- measurement

- Technology

- X-ray

- Configuration

- compact

- Length

Min.: 500 mm

(20 in)Max.: 2,000 mm

(79 in)

Description

The C-FRAME scanner series has been designed to be very compact. Nevertheless, their maintenance is amazingly easy.

They can be used in numerous types of applications.

• PICKLING LINE

• ANNELING

• COLD MILLS ROLLING

• COLD MILLS REVERSING

• COLD MILLS TANDEM

• COATING GALVANIZING LINES

• SKIN PASS

• INSPECTION

• SLITTING / CUTTING

Extremely sturdy Structure

Its Design is extremely simple and robust. it can be installed in less than a day. In addition it supports the harshest environments.

Specifically designed and developed for the flat-rolled metals industry.

LOW INTENSITY

10X LESS X-RAY INTENSITY

Low energy and smaller safety zone tu use the C-FRAME of SCANTECH

SSA3 system

The ULO 3 scanners are all equipped with the IoT (Internet of things) to enable them to connect with any hardware and give them a very long life, without obsolescence.

IoT and data analytics offer new opportunities every day to control and improve your production processes safely.

ln addition, SCANTECH’s complete package of diagnostic and preventive maintenance tools, with real-time data correlation, maximizes the ability to monitor all internai systems and sub-systems during actual gauge use. The C-frame’s electronics have been designed for remote contrai and access – this capability enhances the complete maintenance package.

EMBEDDED SYSTEM

Integrated WEB Server System

The scanner has an integrated WEB server system, combining all the maintenance tools, allowing you to perform maintenance using web browser on any of the following media: PC, MAC, tablet or Smartphone.

Catalogs

No catalogs are available for this product.

See all of SCANTECH‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Hyvolution 2025

28-30 Jan 2025 paris (France) Stand 4T68

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.