- Products

- Catalogs

- News & Trends

- Exhibitions

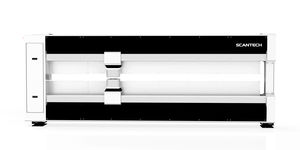

1-axis scanner XF050for measuringX-raycompact

Add to favorites

Compare this product

Characteristics

- Number of axes

- 1-axis

- Applications

- for measuring

- Technology

- X-ray

- Configuration

- compact

- Length

3,500 mm

(138 in)

Description

The HF3 scanner series has been designed to be very solid, for high ambient temperature and very large strip width. Nevertheless, their maintenance is amazingly easy.

SCANTECH release a new solution for measuring the metal coating weight based on its X-Ray proven technology. The XF sensor provides accurate measurement of all finds of coatings

• ZINC : HOT DIP AND ELECTROLYTIC

• TIN

• ZINC AND ALLOYS

• HEAVY ZINC COATING UP TO 600 GSM PER SIDE

ROBUSTNESS

Extremely sturdy Structure

This design offers excellent resistance to torsion and bending of the frame and guarantees greater stability over time.

In standard, the frame and lids are made of anti-corrosion treated steel and painted in light grey (RAL 7035).

OPTION AIR CIRCULATION

Prevent deformation

The scanner is equipped with a fan which ensures that the complete frame is floated with a stabile air temperature. This prevent deformations in the frame.

EMBEDDED SYSTEM

Integrated WEB Server System

The scanner has an integrated WEB server system, combining all the maintenance tools, allowing you to perform maintenance using web browser on any of the following media: PC, MAC, tablet or Smartphone.

EASY ACCESS FOR MAINTENANCE

Maintenance is done on 1 side

The HF 3 scanners have been designed to provide simplicity and fast maintenance operations. For this, all electrical, electronic and mechanical elements have been placed on the same side of the Scanner (maintenace side). This allows a simpler maintenance on a compact production line.

SSA3 system

The HF 3 scanners are all equipped with the IoT (Internet of things) to enable them to connect with any hardware and give them a very long life, without obsolescence.

Catalogs

No catalogs are available for this product.

See all of SCANTECH‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Hyvolution 2025

28-30 Jan 2025 paris (France) Stand 4T68

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.