- Metrology - Laboratory

- Inspection and Monitoring

- Condition monitoring system

- Schaeffler Technologies AG & Co. KG

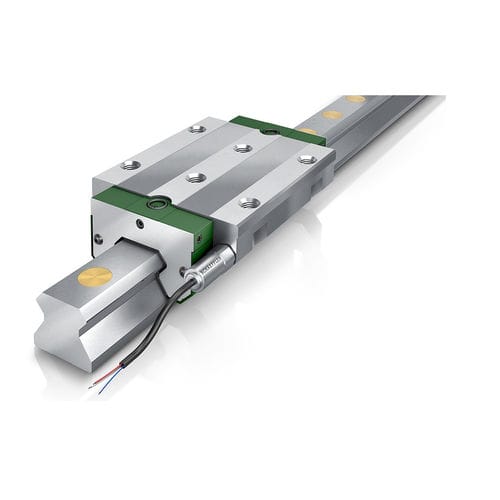

Condition monitoring system DuraSensefieldlubricationEthernet

Add to favorites

Compare this product

Characteristics

- Type

- condition, field

- Applications

- lubrication

- Interface

- Ethernet

- Other characteristics

- smart

Description

Lubrication condition monitoring and requirement-based lubrication

Your benefit:

Machine availability is increased by reducing the number of unplanned downtimes

Planning is made easier, which reduces maintenance costs

Production supply costs are reduced

Comprehensive reasons to use DuraSense

Increased operational security

DuraSense monitors lubrication conditions in linear guidance systems and triggers the signal for a relubricating impulse from a relubrication unit when, for example, insufficient lubrication occurs

Lubrication monitoring

DuraSense ensures that the lubricating impulse also reaches the carriage. If this is not the case (e.g. due to a loose or blocked lubricant supply line), DuraSense triggers the corresponding signal.

Reduced lubricant consumption

Up to 30% less lubricant consumption

Features

One sensor element per carriage

Sensor element on the end face of the carriage; PPU (pre-processing unit) in a stable aluminum housing

PPU with connections for up to seven sensors, as well as Ethernet, field bus, and SPS connections

Connection to the Schaeffler Smart EcoSystem will be possible in the future

Catalogs

No catalogs are available for this product.

See all of Schaeffler Technologies AG & Co. KG‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

HANNOVER 2025

31 Mar - 04 Apr 2025 Hannover (Germany) Hall 5 - 13 - Stand D18 - E41/1

More information

Other Schaeffler Technologies AG & Co. KG products

Mechatronics

Related Searches

- Measurement monitoring device

- Temperature monitoring device

- Environmental monitoring device

- Continuous monitoring device

- Condition monitoring device

- Digital monitoring device

- Process monitoring device

- Remote monitoring device

- Online monitoring device

- Benchtop monitoring system

- Ethernet monitoring device

- Automatic monitoring device

- Vibration monitoring system

- Machine monitoring device

- Compact monitoring device

- Pressure monitoring device

- Level monitoring device

- Smart monitoring device

- Modular monitoring device

- Robust monitoring device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.