- Metrology - Laboratory

- Metrology and Test Equipment

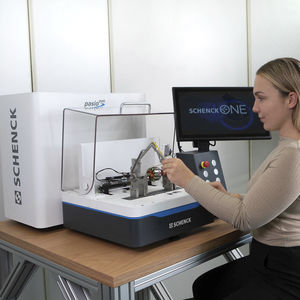

- Vertical balancing machine

- SCHENCK RoTec GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Vertical balancing machine 150 SVMdynamicfor blowersflywheel

Add to favorites

Compare this product

Characteristics

- Orientation

- vertical

- Type

- dynamic

- Applications

- flywheel, for blowers, brake drum, for clutch plates

- Other characteristics

- automatic, single-plane

- Rotational speed

800 rpm

(5,027 rad.min-1)- Weight on rotor

Min.: 5 kg

(11 lb)Max.: 100 kg

(220.5 lb)

Description

• Fully automatic operational sequence

• Manual loading and unloading

• Interfacing with production line is possible

• Fully automatic unbalance correction by drilling, milling, welding or riveting

• Analog or NC axis controlled correction

• Digital measured data processing

Fully automatic single-station machine with integrated high-performance drill unit. Freely programmable control with fault diagnosis and status display. Clamping of the work-pice to the balancing machine by precision adapters with pneumatic unclamping mechanism. Support device located under the work-piece during drilling, to compensate for the drill force. Unbalance evaluation, correction calculation and correction control through PC controlled measuring unit. Manual loading or optional loading for the machine by a hand-operated system and the corresponding conveying technique.

Range of application

Measurement and correction of single-plane unbalance in discshaped rotors with and without shafts, such as flywheels, TMF (twin mass flywheels), brake-drums, gears, clutch-plates, compensation shafts, blowers, etc.

Flexible integration into production line and simple change over of the machine to different rotor types by exchange of work-piece interface adapter and selection of rotor type file.

Unbalance correction by axial or radial drilling in polar or component format. If the initial unbalance is larger than can be corrected by one drilling action, multiple holes can be drilled.

Other unbalance correction methods such as milling, welding, riveting or punching can be integrated into the machine on request. The correction units are flexible and are adapted to the work-piece.

Related Searches

- Measuring device

- Measuring machine

- Test stand

- Automatic test stand

- SCHENCK balancing machine

- SCHENCK dynamic balancing machine

- Automatic measuring machine

- SCHENCK horizontal balancing machine

- Diameter measuring machine

- SCHENCK vertical balancing machine

- SCHENCK automatic balancing machine

- SCHENCK rotor balancing machine

- SCHENCK high-accuracy balancing machine

- Material test bench

- SCHENCK modular balancing machine

- SCHENCK hard bearing balancing machine

- Fatigue test stand

- SCHENCK fan balancing machine

- Engine test bench

- SCHENCK universal balancing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.