- Packing - Handling - Logistics

- Conveying

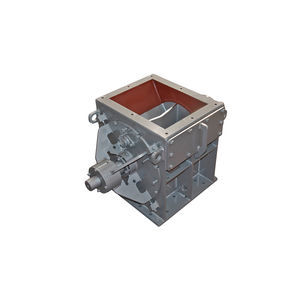

- Bulk material rotary valve

- Scheuch COMPONENTS GmbH

Bulk material rotary valve ZSL

Add to favorites

Compare this product

Characteristics

- Applications

- for bulk materials

Description

A rotary valve can take on lots of different jobs, depending on what is required of it, but its main task is to discharge dosed quantities of bulk material that can then move on to further treatment stages.

Rotary valves that are installed under silos and other repositories reduce the pressure that the bulk materials exert on the immediately adjacent components in a transport chain. Their dosing-based method of discharging also takes the strain off trough screw conveyors and other systems, including scales. Not only that, but rotary valves even provide burn back protection in cases where they are used with combustible materials.

WHAT TYPES OF ROTARY VALVE ARE AVAILABLE?

Rotary valves come in a variety of designs to suit all kinds of different tasks. Please get in touch if you need any information about the specific features that our products contain – whether you need a small rotary valve or something suitable for handling large volumes, Scheuch COMPONENTS has a solution to suit your requirements.

This type is suitable for free-flowing dust, high-volume chips and light fibres. The ZSL has rotor blades with antistatic, elastic sealing lips which are built into a bolted casing.

Max. differential pressure: 8,000 Pa

Throughput volume: 35 to 9,122 m³/h

Catalogs

ROTARY VALVES

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.