- Products

- Catalogs

- News & Trends

- Exhibitions

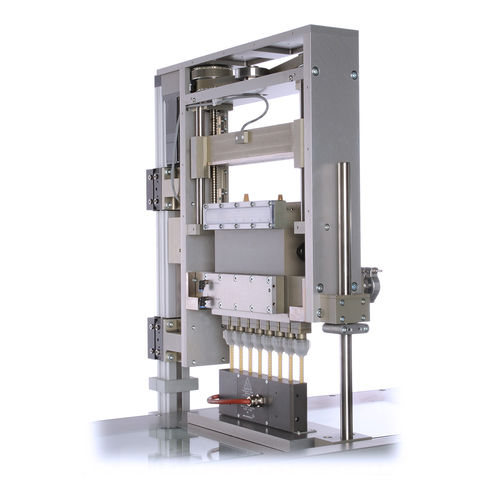

High-viscosity media dosing dispenser Dos P-Xfor low-viscosity liquidsfor medium-viscosity mediaadhesive

Add to favorites

Compare this product

Characteristics

- Product

- for high-viscosity media, for low-viscosity liquids, for medium-viscosity media, adhesive, silicone, lubricant, for shear-sensitive media

- Type

- piston

- Applications

- for the automotive industry, for the plastics industry, for the electronics industry

- Other characteristics

- single-component, high-precision, two-component

Description

Multi-piston dispensers are used for the output of large batch quantities and for short cycle times. These systems can pot several workpieces in a single potting cycle. They are particularly suited for potting a large number of small workpieces, especially when dispensing in a vacuum. Their unrivaled performance is the result of distributing the filling, evacuation and ventilation time among many workpieces. Multi-piston dispensers are made of several functionally interconnected single dispenser outlets. Each outlet is controlled by individual inlet/outlet valves and monitoring sensors. A shared expulsion unit guarantees absolutely simultaneous and identical dispensing from all outlets. One or more nozzles can be disabled by controlling individual valves for more flexibility in the event that not all of the holders contain workpieces. These systems achieve perfectly precise dispensing accuracy combined with a long service life, regardless of the number of single outlets used.

• High part throughput per unit of time (up to 48 nozzle potting possible)

• Consistent quantity and mixing ratio through common lifting mechanism

• Simultaneous discharge of cylinders through common lifting mechanism

• Direct nozzle control allows for alternating placement of the workpiece carriers

• Sensor-based monitoring of inlet and outlet valves as well as cylinder filling for each dispenser

• Temperature control with mixing tube heater (optional)

Catalogs

Catalogue 2019

66 Pages

Related Searches

- Volumetric dosing unit

- Liquids dosing unit

- Automatic dosing unit

- High-precision dispensing system

- Continuous dispensing system

- Resin dispensing system

- Adhesive dispensing system

- Dosing unit for the electronics industry

- Dosing unit for the automotive industry

- Dosing unit for the plastics industry

- Manual dispensing system

- Piston metering system

- Two-component dispensing system

- Single-component dispensing system

- Silicone dispensing system

- Vacuum dispensing system

- Dispensing system with gear pump

- Low-capacity dosing dispenser

- Lubricant dosing dispenser

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.