Butt welding machine GAA100standalonefor steelcompact

Add to favorites

Compare this product

Characteristics

- Technique

- butt

- Configuration

- standalone

- Applications

- for steel

- Other characteristics

- compact

Description

Mobile and stationary flash butt welding machines

and stand-alone systems for railway tracks

Efficiency and reliability with the help of flash butt welding

Flash butt welding is the most reliable joining technology for track

construction and it is a proven fact that it provides the lowest failure

frequency. Schlatter offers welding machines that run in different

customized systems.

Welding machines and systems

Worldwide flash butt welding has become increasingly popular for production of continuous welded

rails.

Mobile rail welding systems

With the help of the mobile welding systems, continuous track sections are produced directly in-track.

With our high level of system expertise, we are able to assemble complete mobile rail welding systems from compact welding machines, carrier vehicles, power generators and further

auxiliary equipment.

Stationary rail welding systems

Stationary welding systems are mainly used in large welding plants for joining short rails to long rails. Furthermore, components for switch construction can be welded.

The Schlatter welding machines are the heart of this welding process and can be supplemented with additional machines to create a complete system.

Stationary rail welding machines GAAS80 and GAA100

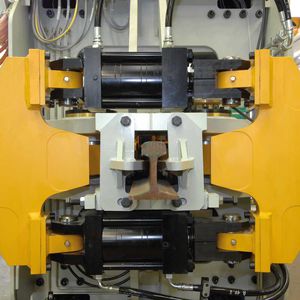

System GAA100

The GAA100 is used for welding components in turnout manufacturing plants.

The wide welding range allows high quality welding of nearly all types of components used for turnouts.

The four clamping units with 1000 kN force each ensure that the parts do not slip during upsetting.

Worldwide the GAA100 successfully welds high resistant manganese frogs with rails with the intermediate stainless steel insert.

Catalogs

Other Schlatter products

Stationary and Mobile Flash Butt Welding Systems for Rails

Related Searches

- Welding system

- Automatic welding system

- Metal welding system

- Arc welding system

- Automatic crimp applicator

- Resistance welding system

- Standalone welding system

- Compact welding system

- Mounting machine

- Steel welding system

- Butt welding machine

- CNC welding system

- Spot welding system

- Integrated welding system

- Programmable welding system

- High-speed welding system

- Assembly machine for industrial applications

- Copper welding system

- Cost-effective welding system

- Vertical welding system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.