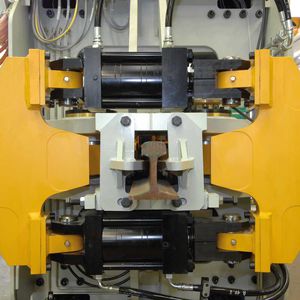

Compact welding system Supra Multiflexintegrated

Add to favorites

Compare this product

Characteristics

- Other characteristics

- compact, integrated

Description

Mobile rail welding systems Supra Multiflex and Supra Roadflex

For mobile welding of continuous welded rails, these machines are normally integrated into an autonomously operating rail welding system. These systems are equipped with diesel-generator set,

hydraulic unit, cooling unit and lifting device.

Supra Multiflex container-based rail welding system

Container systems are especially suitable for welding continuous welded rails directly in new railway track. They are also often used semi-stationary in the depot or near the job site for preparation of long welded rails for a section in a new railway line.

Supra Roadflex truck-based rail welding system

The truck-based system is highly flexible as it is self-propelled and can move from one job site to the next within a short time.

Customized system solutions Optionally, the welding machines AMS60, AMS100 and AMS200 can also be purchased separately and installed in customer-specific vehicles such as pure

track vehicles, in their own rail-mounted trucks or in excavators. There is also a stand-alone solution for stationary operation in a factory

Supra Multiflex

Container systems are especially suitable for welding in new railway lines where a lot of new rails have to be placed and many welds have to be carried out. They are also often used semi-stationary either in the depot or close to the job site where they weld long welded rails for a certain section of new railway line before they are taken to another section.

Schlatter offers a compact 24-feet container that contains all equipment in a space-saving manner.

Catalogs

Other Schlatter products

Stationary and Mobile Flash Butt Welding Systems for Rails

Related Searches

- Welding system

- Automatic welding system

- Metal welding system

- Arc welding system

- Automatic crimp applicator

- Resistance welding system

- Standalone welding system

- Compact welding system

- Mounting machine

- Steel welding system

- Butt welding machine

- CNC welding system

- Spot welding system

- Integrated welding system

- Programmable welding system

- High-speed welding system

- Assembly machine for industrial applications

- Copper welding system

- Cost-effective welding system

- Vertical welding system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.