Pneumatically-operated clamping device automatic

Add to favorites

Compare this product

Characteristics

- Type

- pneumatically-operated

- Other characteristics

- automatic

Description

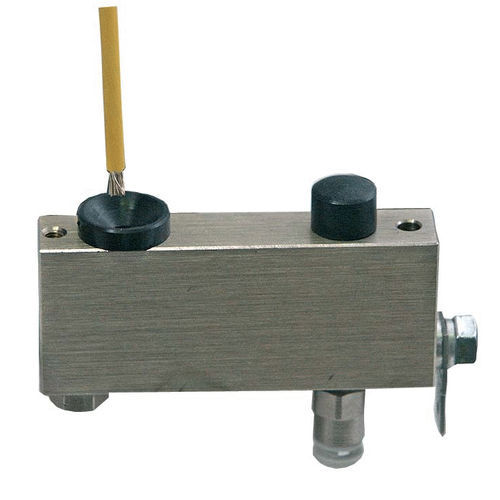

Connect conductors quickly and conveniently.

Simply insert the conductor into the pilot hole until it presses against the bottom of the hole.

This activates the clamping process to the terminal of the conductor.

At the end of the test, the clamps are all reopened together.

Practical and reliable.

• Extensive selection of standard contactings for different lead diameters

• Solid and robust design

• Customized solutions based on our standard solutions

The so-called “pneumatic clamp” is supplied with compressed air. Test objects are often only equipped with free lead ends without plug. The lead to be contacted is inserted approx. 1cm in the clamp´s borehole. At the borehole´s bottom there´s a flexible valve plate. As soon as it is pressed down by the lead, the integrated valve reacts and makes a clamping cylinder in the clamp push against it. By this the contacting is established.

A black push button is installed on the clamp to disconnect the contacting.

It is no problem to operate any number of clamps by means of the compressed air supply. In case the entire compressed air supply is interrupted, all clamps open at the same time. This is perfect, as it is possible to quickly open all contact points in parallel when a test is finished.

SCHLEICH delivers a wide range of proven pneumatic clamping devices.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Schleich GmbH‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.