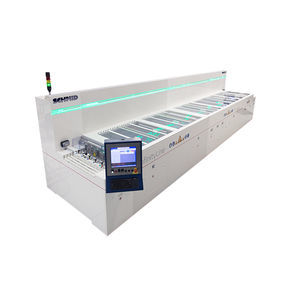

Laser texturing machine DW PreTex

Add to favorites

Compare this product

Characteristics

- Type

- laser

Description

Cost-effective texturing of diamond-wire-cut multi-wafers

DW PreTex can be integrated into the existing production as a modular wet process system without additional requirements – both for wafer and cell manufacturers. For DW PreTex uses common materials used in the PV industry. The operating costs are less than 0.01 Euro per wafer. In addition, the process achieves extremely uniform surfaces with reflection values down to 21 %.

The inline process developed by SCHMID provides enormous savings for the PV industry. DW PreTex requires only one process step to allow the processing of diamond-wire cut multi-wafers with the proven standard texture HF/HNO3. Thanks to the perfect pre-treatment by DW PreTex, the diamond-wire cut wafers have more uniform surfaces than slurry-cut wafers. Thus further increases in cell efficiency are possible.

DW PreTex is available in two versions: as a separate single unit that roughens the surface of the wafers and then uses the available texture capacity, or as a combined line for complete texturing. Due to the modular design, the inline process can be designed for serial production of up to 4,500 wafers per hour.

Creates a surface with low reflection value down to 21 %

Water-based inline process

Available as single unit and inline with acid texturing

Can be easily integrated into existing wafer and cell production

Total Cost of Ownership per wafer < 0.01 Euro

Catalogs

No catalogs are available for this product.

See all of SCHMID‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.