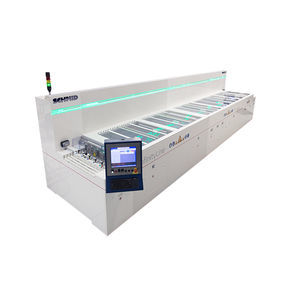

Chemical wafer etching machine for the microelectronics industry

Add to favorites

Compare this product

Characteristics

- Type

- chemical

- Applications

- for the microelectronics industry

Description

The Edge Isolation + PSG Etching Inline System combines several process steps in one system with modular design. On the one hand the emitter layer on the rearside of the wafer generated during the diffusion process is unilaterally isolated from the front side of the wafer in order to prevent malfunction of the solar cell. On the other hand the phosphorous silicate glass (PSG) is removed from the wafer surface.

During the edge isolation the emitter is protected by the water mask developed and patented by SCHMID. Special profiled transport rollers ensure that the chemistry comes into contact exclusively with the rearside, and therefore little chemistry is consumed.

For the etching of the phosphorus silicate glass special holding-down shafts are used instead of shafts fitted with O-rings. These do not leave impressions on the wafers. In addition, the modified conveyor allows easy cleaning of the shafts. Therefore, organic pollution of the wafers by the transport system is excluded.

The rinsing between the individual process steps ensures minimum drag-out. SCHMID’s multiple cascade technology reduces the consumption of DI water. Thanks to the modular design of the inline system, throughput and process steps can be adapted to customers’ needs. In addition, special cleaning processes are available for PERC cells.

Catalogs

No catalogs are available for this product.

See all of SCHMID‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.