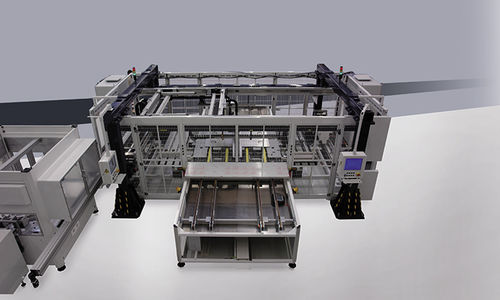

Linear transfer machine CNC8-positionmachining

Add to favorites

Compare this product

Characteristics

- Type

- linear

- Control type

- CNC

- Number of positions

- 8-position

- Other characteristics

- machining

Description

The strings are fully automatically transferred from the stringer unit of the Tabber Stringer to the Layup Station where they are taken over by a gripper system. Camera systems inspect them for breakage and orientation, defect strings are sorted out. Two combined cutting-bending units shorten the bus bars to the required length and exactly bend them to the required angle before they are positioned on the glass plate with EVA foil. The Layup Station is already prepared for an upgrade of the line to 60 MW, because its modular configuration is designed for the integration of an additional Tabber Stringer on the same foot print.

Gentle handling via Bernoulli grippers

Accurate positioning of the strings on the glass

Exact cutting and bending of the bus bars

Easy line upgrade to 60 MW

Low maintenance expenses

Intelligent buffer system

Catalogs

No catalogs are available for this product.

See all of SCHMID‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.