- Industrial machines and equipment

- Mixing and Dosing

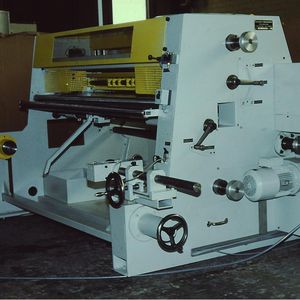

- Vacuum dispersion system

- Schmidt & Heinzmann GmbH & Co KG

Vacuum dispersion system dustliquidsresin

Add to favorites

Compare this product

Characteristics

- Other characteristics

- vacuum

- Applications

- dust, liquids, resin

Description

Solutions for the automatic and precise resin and filler dosage from raw material tanks into mixing vessels. This fast filling process is based on PLC stored recipes and realized by gravimetrical weight control systems.

For mixing the resin paste with filler and additives a broad range of dispersion machines for batches from 100 to 4,000 kg are available. They offer features, such as variable speed control, high performance stirring discs, inline weighing scales, wall scrapers, temperature measurement and control as well as vacuum options.

Dosage of liquid and solid materials

Semi and fully automatic solutions

Working platforms

High performance dispersion machines for mixing

Temperature controlled mixing

Dust extraction units

Explosion protection solutions

Catalogs

No catalogs are available for this product.

See all of Schmidt & Heinzmann GmbH & Co KG‘s catalogsOther Schmidt & Heinzmann GmbH & Co KG products

PRODUCTS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.