- Industrial machines and equipment

- Mixing and Dosing

- Continuous mixing system

- Schmidt & Heinzmann GmbH & Co KG

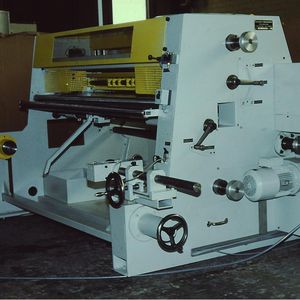

Continuous mixing system

Add to favorites

Compare this product

Characteristics

- Options

- continuous

Description

S&H offers excellent multi component pumping, dosing & mixing systems (PDM units) that allow a precise combination of the thickener or hardener with the pre-mixed resin paste. In static or dynamic mixers the paste is consistently enriched with the thickener or hardener by gravimetric, volumetric or mass flow based pumping. This guarantees homogenous pastes of high quality. Whenever needed, it is easy to automatically clean the PDM unit including the entire pipe system by the moveable cleaning pump system.

Also the dosage of a 3rd or 4th component, usually color pigments, can be implemented in the PDM unit and its overall PLC system. A height level sensor on each doctor box of the SMC line controls the PDM unit and ensures the ideal amount of resin in the doctor boxes. By using recipes, the reciprocal process is guaranteed and allows to work with different resin systems including other additives, all in a wide range of viscosities.

The PDM units are essential for the production of consistent high quality SMC material. Therefore we developed reliable and innovative PDM systems in different sizes and features.

Static and dynamic mixing systems

2, 3, 4 and 5 components units for use of multiple colors and thickeners/ hardeners

Mass flow meter for precise and reliable dosage of color pigments, thickener and hardener

Robust scales for gravimetrical dosage of resin

Component tanks in stainless steel

Level sensor control for all tanks

Intermediate resin tank for continuous production

Automatic resin level control in doctor boxes

Moveable automatic cleaning pump for fast, efficient and convenient cleaning

Catalogs

No catalogs are available for this product.

See all of Schmidt & Heinzmann GmbH & Co KG‘s catalogsOther Schmidt & Heinzmann GmbH & Co KG products

PRODUCTS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.