- Production Machines

- Other Manufacturing Equipment

- Glass product production line

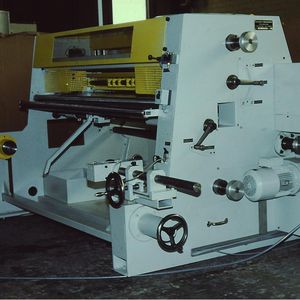

- Schmidt & Heinzmann GmbH & Co KG

Glass product production line bi-component fiberautomatic

Add to favorites

Compare this product

Characteristics

- Finished product

- bi-component fiber, for glass products

- Other characteristics

- automatic

Description

S&H builds world-class SMC production lines for manufacturing of glass and carbon fibre SMC. They can be customized to match specific requirements. Our produciton lines can be equipped e.g. with

high precision doctor boxes

robust and reliable choppers

pre-impregnation units

de-aeration units for reduction of trapped air.

A wide range of high-end impregnation units enable the production of high quality SMC material.

Production lines for all needs

Use of different resins, low and high viscosities

Manual and automatic doctor boxes

Advanced tempering concepts

Roving cutters for up to 4,800 tex

Additional reinforcements through fabric unwinders and UD roving inlets

Specific solutions for carbon fiber SMC

Pre-impregnation & de-aeration units

High performance compaction sections

Metal detector

Resin height control

Sheet weight area control systems

Friction winders, turret winders, festooners and combination systems

Packaging in standard rolls (up to 400 kg), jumbo rolls (up to 1,200 kg) or box material

Catalogs

No catalogs are available for this product.

See all of Schmidt & Heinzmann GmbH & Co KG‘s catalogsOther Schmidt & Heinzmann GmbH & Co KG products

PRODUCTS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.