- Production Machines

- Forming Machine

- Fiber forming machine

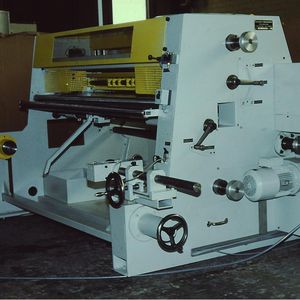

- Schmidt & Heinzmann GmbH & Co KG

Fiber forming machine fabrictextileautomatic

Add to favorites

Compare this product

Characteristics

- Treated material

- fiber, fabric, textile

- Operating mode

- automatic

Description

Preforming, particularly of dry textile fabric or other semi-finished products, is regarded as key technology in the production of continuous-fiber-reinforced plastic components by means of the RTM process (Resin Transfer Molding). We enable our customers to produce complex 3D component contours within short cycle times with robust process technology as well as reproducible preform quality.

With our innovative machine technology, we are setting new standards in producing dry fiber based reinforcements and prepreg materials. The transportation unit, adapted to the product specific geometry of the cutting, allows tension-free feeding of the individually cut fabric to the mould or an intermediate heating station. Alternatively, the material can be fed directly onto the lower tool outside the pressing unit by means of a shuttle table.

The core equipment consists of the draping tool, which can be opened and closed by the pressing unit. The lower part of the mould is rigid, whereas the upper part consists of segmented draping stamps, thus allowing a sequential forming of the semi-finished material. Handling units mounted in the working area of the pressing station coordinate the material transfer from the transport device onto the draping tool. Simultaneously to the closing of the draping tool, the handling units can induce local membrane tension to influence the draping process positively. In the course of an integral production process, it is possible to introduce additional component parts such as reinforcing elements or core materials for sandwich constructions.

Catalogs

No catalogs are available for this product.

See all of Schmidt & Heinzmann GmbH & Co KG‘s catalogsOther Schmidt & Heinzmann GmbH & Co KG products

PRODUCTS

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.