- Machine-tools

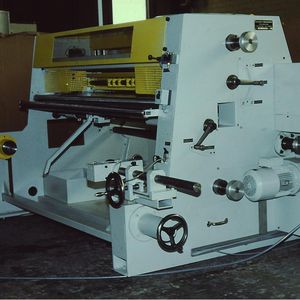

- Finishing Machine

- Deburring deburring machine

- Schmidt & Heinzmann GmbH & Co KG

Deburring deburring machine edgetrimmingbrush

Add to favorites

Compare this product

Characteristics

- Associated function

- deburring, trimming, edge

- Type

- brush

- Other characteristics

- automated

Description

Schmidt & Heinzmann offers fully automated handling of coating, deburring and loading of power wash following the pressing of parts.

The cooling stations have to be customized to ensure the requested dimensions. An optional section provides the exact part positioning.

Deburring and edge trimming are realized by integrated machinery ensuring accurate dimensioning and deburring of the parts.

The entire handling, including transportation, is done by robots. Their design and layout depend on the parts and the factory layout.

Precise deburring for precise plastic parts/ components

Complex programing of the deburring unit to ensure tolerances and mechanical interfaces

System including individual deburring fixtures

Cleaning robot using a brush and compressed air

Robot fixed on a movable device allowing easy access to the mold

Cover for secure mold transport over robot area

Catalogs

No catalogs are available for this product.

See all of Schmidt & Heinzmann GmbH & Co KG‘s catalogsOther Schmidt & Heinzmann GmbH & Co KG products

PRODUCTS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.