- Hydraulics - Pneumatics

- Pump

- Centrifugal pump

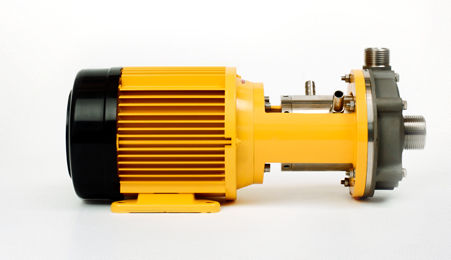

- SCHMITT - Kreiselpumpen GmbH & Co. KG

Centrifugal pump UP-DO seriesfor chemicalswith electric motorfor the food industry

Add to favorites

Compare this product

Characteristics

- Technology

- centrifugal

- Fluid

- for chemicals

- Operation

- with electric motor

- Domain

- for the food industry, laboratory

- Applications

- lubrication

- Material

- EPDM, carbon steel, stainless steel, PTFE

- Protection level

- chemical-resistant

- Other characteristics

- dry, mechanical, seal

- Flow

460 l/min

(121.51914 us gal/min)- Head

39 m

(127'11" )- Power

Min.: 0.18 kW

(0.24 hp)Max.: 5.5 kW

(7.48 hp)

Description

In the UP-Do Pump Series, the motor power is transmitted without slip directly to the pump impeller with a rigid shaft (no magnetic coupling). A double mechanical seal (back to back) prevents the leakage of the media to be pumped and ensures the leak proof sealing of the centrifugal pump. All parts that are in contact with the medium are made solid of stainless steel (1.4581). The cooling and lubrication of the mechanical seals is carried out through a separate seal water circle.

Advantages of the UP-DO Pump Series:

with a connected seal water circle, the pump cannot be damaged, neither through operator error or malfunctions in the plant (dry run safe under certain conditions).

applicable for media without lubricating properties (e.g. varnishes and paints)

also applicable for higher viscosities or metallic particles in the medium

the highest chemical resistance also at high temperatures up to +150° C

robust, thick-walled design, solid stainless steel fine cast (no thin-walled extruded sheet metal)

low-maintenance through an optimal adaptation to the medium to be pumped

long-lasting and wear resistant, various types of designs for almost all operating conditions

open impeller (i.e. solids up to 3 mm grain size and 10 Vol. % possible)

easy to maintain (wear parts and the mechanical seal can be changed swiftly)

universally applicable, quiet and compact

various chemical resistant materials can be supplied as stock items

The UP-Do Pump Series is designed for all sorts of applications and is perfectly suitable for the transmitting operation in stainless steel plants as well as for severe thermal stress environments.

Catalogs

Other SCHMITT - Kreiselpumpen GmbH & Co. KG products

Pumps

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.