- Metrology - Laboratory

- Optical Component

- Automatic ophthalmic lens blocker

- Schneider Optical Machines

Automatic ophthalmic lens blocker SPP, CC Series

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

Description

INFORMATION

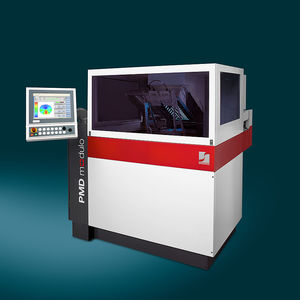

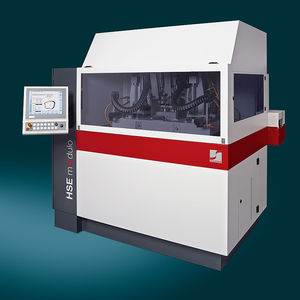

The fully automated spin protection system, SPP Modulo, optimally protects lenses during surfacing utilizing UV-curable liquid protection layers. Problems with wrinkles, bubbles or detaching, commonly known with current taping solutions, are a thing of the past. Ideal preconditions for autoblocking.

The smart automation system handles eight lenses at a time, swiftly transferring them from station to station. While two lenses are covered with the thin film lacquer protection layer, another two are already being cured using UV light at the next station. At the same time, the next two lenses are loaded and another two are transferred back to the job tray.

The UV-curable protection layer is evenly distributed across the lens optimally covering it while adhering tightly to it – even with extremely curved lenses or extreme flat top bifocals. Bubbles or wrinkles are prevented that often result in power or cosmetic defects.

One filling of the lacquer tank lasts all shift long and can be refilled quickly and easily, resulting in uninterrupted processing and minimum downtime. No hassles with tape replacement.

After processing, the protection layer can be removed easily with SCHNEIDER’s solutions for deblocking and tape-stripping.

BENEFITS

Fully automated lens protection

No bubbles, wrinkles, or detaching – even with extreme lenses

Uninterrupted processing all shift long

Fast and easy lacquer refill

Ecological solution resulting in significant waste reduction

More cost effective than tape

Designed for Modulo Control Center integration

Catalogs

No catalogs are available for this product.

See all of Schneider Optical Machines‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.