- Products

- Catalogs

- News & Trends

- Exhibitions

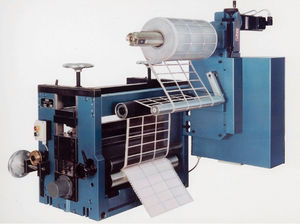

Steel cutting machine CNCcontourrotary

Add to favorites

Compare this product

Characteristics

- Material

- for steel

- Control type

- CNC

- Associated function

- contour

- Other characteristics

- rotary

Description

Rotary cutting technologies are employed for the form cutting of materials, laminates, non-wovens and films as thin as 10μm. Using state of the art CNC-technique almost any imaginable cutting contour can be achieved. Small quantities are mostly die cut with monobloc cutting cylinders, made of tool steel or by the use of magnetic cylinders/flexible dies. Larger quantities are preferably die cut with segmented tools. High alloy steel, powder metallurgical steels or tungsten carbide are primarily used as cutting segment materials. Die cutting segments can be exchanged easily when damaged. All die cutting materials serve as well as counter cutting materials. In addition coatings can be chosen to protect against corrosion, wear and sticky materials.

These cutting cylinders can be mounted into existing frames or into high precise modules made by Schobertechnologies. Schobertechnologies modules offer features for setting and controlling the die cutting/converting gap by microns. Exact product separation, wear compensation and maximum life time of the die cutting tool go without saying.

Catalogs

No catalogs are available for this product.

See all of SCHOBER‘s catalogsRelated Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Knife cutting system

- Precision cutting system

- Fabric cutting system

- Steel cutting system

- Die cutting machine

- Contour cutting system

- Rotary cutting system

- Roller cutting machine

- Stacking cutting system

- Transversal cutting system

- Rotary operated cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.