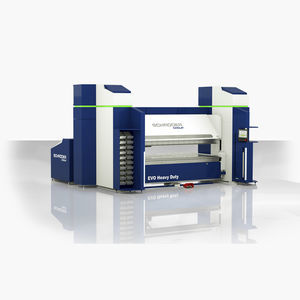

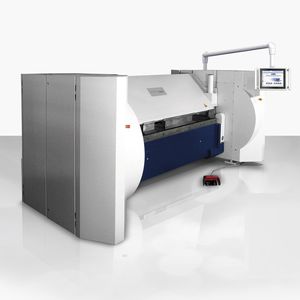

Sheet metal swivel folding machine EVO DuoBendhydraulicautomatic

Add to favorites

Compare this product

Characteristics

- Material

- sheet metal

- Operation

- hydraulic, automatic

- Folding length

3,240 mm, 4,040 mm

(127.6 in, 159.1 in)

Description

The new motorized folding machine EVO DuoBend owes its name „DuoBend“ to its two independently operated folding beams. With the EVO DuoBend, the Schröder Group is once again increasing its flexibility in the area of sheet metal folding many times over: Products for container construction, vehicle construction or conventional folding applications, such as heavy sheets with counterbends, can be manufactured efficiently.

Details

Software control

POS 3000 3-D Graphic control on swivelling arm

Radius function

Remote maintenance via Internet

External programming (PC-Version 1. Licence)

Back gauge

Gauge table 1700 mm as U-shape divided support plates with steel balls

Lateral angle gauge right and left side 1500 mm (outside)

Suction plates in gauge table, controlled via POS 3000

2 pneumatic pop up square arms assembled aisle side, program-controlled

Gauge axis in front

Clamping beam

Clamping beam stroke: 850 mm

Clamping beam geometry: 180°

Fully automatic tool changer WZS 6500: for clamping beam tools with a hydraulic tool clamping device (a total of 8 axis) for max. tool height of 500 mm,

two asynchronously movable tool changers with one gripper unit each

Folding beam

Two folding beams, program-controlled

Mechanic tool clamping device (screwed) (WZS 19000)

Motorized folding beam adjustment 150 mm

Motorized folding center adjustment 370 mm

Motorized central crowning device in both beams

Work safety

Protection via light curtain controlled by safety-PLC for operation

from the rear

Safety fence with lateral access door

Others

Standard machine without tools

Working height 1160 mm

Foot switch, anchor plates incl. dowels, decentralized lubrication system

Air conditioner on both switch

Catalogs

No catalogs are available for this product.

See all of Schröder Group‘s catalogsRelated Searches

- Plaiting machine

- Metal bender

- Sheet metal swivel folding machine

- Sheet metal folding machine

- Automatic metal bender

- Electric metal bender

- Manual swivel folding machine

- CNC swivel folding machine

- Hydraulic folding machine

- Hydraulic swivel folding machine

- Precision swivel folding machine

- Large swivel folding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.