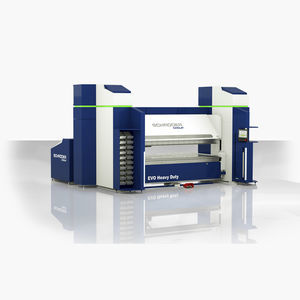

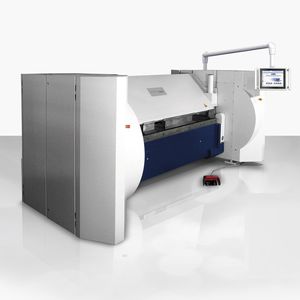

Sheet metal swivel folding machine MAKUelectric

Add to favorites

Compare this product

Characteristics

- Material

- sheet metal

- Operation

- electric

- Folding length

2,520 mm, 3,220 mm

(99.2 in, 126.8 in)

Description

The motorized folding machine MAKU is the ideal entry into motorized thin sheet metal processing for up to 2.5 mm thick sheet metal. For plumber- and repair workshops this type of machine respresents a very versatile solution – the U in its name stands for „universal“. No other machine on the market offers so much clearances. It is the first machine in the world with a two axis back gauge for automatic conical bending.

Details

Standard configuration

Software control:

New Classic Bend with touchscreen turnable on switch cabinet

Radius function

Clamping beam

45° clamping beam with clearance 65 mm on the rear

Drive: middle motor 0.75 kW

Clamping beam stroke: 150 mm

Clamping pressure adjustment via handwheel (without tools)

Clamping beam tools:

tinsmith blade or optionally sharp nose blade 20°, ca. 700 N/mm², directly screwed to clamping beam

Folding beam

Drive: 1.5 kW (converter-controlled)

Manual adjustment: 30 mm

Folding blades 10 mm and 25 mm (from MAKU 3200: 15 mm and 25 mm); 700 N/mm²

Bottom beam

45° bottom beam with clearance 54 mm on the rear

Bottom beam blade, one-piece, 8 mm lowered, ca. 700 N/mm², from 30 mm: 8 mm lowered, depending on chosen gauge

without finger grooves

with finger grooves 6 mm or optionally 10 mm

Others

Foot switch

Anchor plates incl. dowels

Catalogs

No catalogs are available for this product.

See all of Schröder Group‘s catalogsRelated Searches

- Plaiting machine

- Metal bender

- Sheet metal folding machine

- Sheet metal swivel folding machine

- Automatic metal bender

- Electric metal bender

- Manual swivel folding machine

- CNC swivel folding machine

- Hydraulic folding machine

- Hydraulic swivel folding machine

- Precision swivel folding machine

- Large swivel folding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.