- Production Machines

- Forming Machine

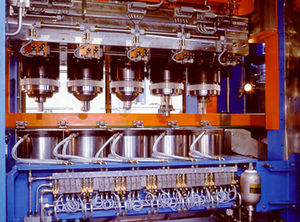

- Hydraulic press

- SCHULER - MÜLLER WEINGARTEN

Hydraulic press MHS forgingdeep drawingironing

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic

- Function

- deep drawing, forging, ironing

- Other characteristics

- vertical, horizontal, economical

- Force

16,000 kN

Description

Hydraulic presses can form over almost unlimited stroke lengths under force, and therefore are well suited to wall ironing. In addition to traditional vertical forging systems, Schuler also offers horizontal presses. With ingenious integration of two die chambers in this design, the return stroke of the slide can also be used for forging, thereby increasing productivity.

As a rule, one ironing operation is sufficient for calibrating precise parts. Long, thin walled parts are generated in one stroke by relatively large reductions in the wall thickness on presses with long stroke length and several ironing rings arranged consecutively. The blanks are pulled through the die with the punch. In one cycle, the wall thickness is reduced precisely to the required dimension, the ultimate shape is created and the surface is smoothed.

Your advantages

high part quality in terms of accurate dimensions and shape, as well as surface quality

economical production with combined deep-drawing and ironing operations in one forging procedure

no limits on part length due to unlimited working strokes of hydraulic press systems

high output performance, particularly with horizontal press systems using two die chambers

Catalogs

The entire world of forging

84 Pages

Other SCHULER - MÜLLER WEINGARTEN products

Forging Technology

Related Searches

- Schuler industrial press

- Schuler hydraulic press

- Schuler forming press

- Schuler automatic press

- Schuler electric press

- Vertical press

- Ram press

- Pneumatic press

- Schuler cutting press

- Schuler stamping press

- Process press

- Schuler production press

- Schuler mechanical press

- PLC-controlled press

- Bending press

- Schuler press for the automotive industry

- Cambering press

- C-frame press

- Press for industrial applications

- Sheet metal press

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.