- Products

- Catalogs

- News & Trends

- Exhibitions

Rotary screening machine FCRfor bulk materialshigh-frequencystainless steel

Add to favorites

Compare this product

Characteristics

- Type

- rotary

- Material

- for bulk materials

- Other characteristics

- high-frequency, stainless steel

Description

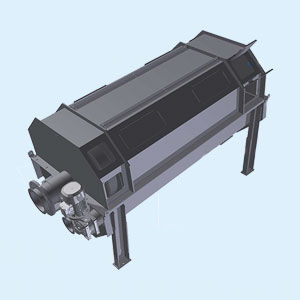

This rotary combined machine is used for the separation and subsequent dewatering and compacting of the solid content in wastewater coming from industrial and municipal plants.

The machine is composed by:

External structure in stainless steel AISI304 L/316 L

Screw in high carbon steel or stainless steel AISI304 L/316 L

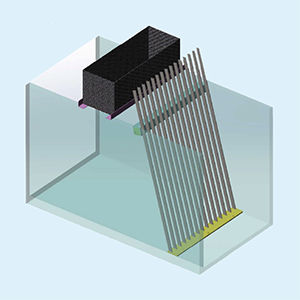

Outer rotary loading drum concentric to the loading basket (drilled sheet or wedge wire)

Loading basket

Transport section: tube or U-shape trough

Discharging section: with compactor

Driver and gear reducer

Supporting adjustable foot

The solid in the sewage enters in the basket occluding it, bringing an increase of the level before the filter. A level sensor sends a signal to start the rotation of the screw screen and consequentely of the outer rotary loading drum. During rotation the outer rotary loading drum discharges solid in the screw conveyor with the aid of outer rotary loading drum washing system. The outer surface of the screw screen is further cleaned by brushes fixed on the outer side screw so that makes cleaning action during rotation. The compactor located at the end of the transport section, on top of the machine, makes compaction and dehydratation of solid, to reduce weight and volume.

Vantaggi

Low speed of rotation and no intermediate supports

Self-cleaning with brushes fit on the screw

Low maintenance and low initial investment

Considerable reduction of volume and weight at the end of processing (up to 50%)

High percentage of solid removed

Catalogs

No catalogs are available for this product.

See all of SE.F.T.‘s catalogsRelated Searches

- Screening unit

- Bulk material screening unit

- Stainless steel sieving machine

- Sorting screening machine

- Liquid sieving machine

- Rotary screening machine

- Spiral screener

- Separator screen

- Drainage screener

- High-frequency screening machine

- Centrifugal sieving machine

- Sewage sludge screener

- Sludge treatment separator screen

- Sieving machine with compactor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.