- Products

- Catalogs

- News & Trends

- Exhibitions

Electric self-propelled trailer 2-axleliftingfor autoclaves

Add to favorites

Compare this product

Characteristics

- Motor type

- electric

- Number of axles

- 2-axle

- Options

- lifting, for autoclaves

- Carrying capacity

Max.: 100 t

(110.23 us ton)Min.: 10 t

(11.02 us ton)

Description

Integrate autoclaves seamlessly in your production line, eliminating extra handling

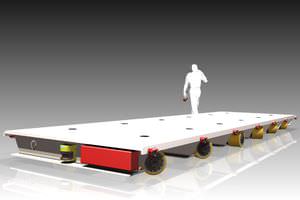

•ultra-low vehicle height -250mm, maximazing available autoclave space

•capacity: from 10 to 100 ton+

•fork design or pallet transporter

•fully omni-directional

•narrow wheel track

•integrated lifting system

•mechanical guidance options

•precision up to 1 mm

•radio controlled

•all electric and clean technology

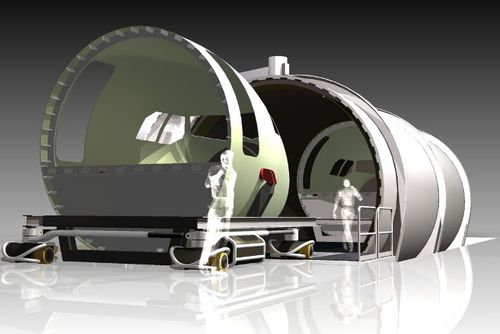

Loading an autoclave or an oven is often a tedious and time-consuming task: products are transported to the autoclave location, transferred by crane onto a rail cart. When the rail cart is full a towing unit pushes the rail cart into the autoclave. The reverse process goes for unloading as well.

Seaqx offers a solution to make autoclave loading more efficient: the same vehicle that transports the product through the assembly line (winding stations, layering stations, milling stations,...) can be used to introduce the products directly into the autoclave, no need transferring them on to other carts, and streamlining production flow. Using the integrated lifting stroke, the product can be picked up and moved, directly from floor level or using a pallet or jig depending on the kind of load.

To accomplish its task successfully, the autoclave loader needs to be as low as possible, to maximize available space inside the autoclave. The Seaqx autoclave loader can be as low as 250 mm. The same autoclave can be used to cure larger parts, before the acquisition of a larger one needs to be contemplated.

Catalogs

No catalogs are available for this product.

See all of Seaqx NV‘s catalogsRelated Searches

- Wheel-mounted tug

- Electric tug

- Electric transfer car

- Handling transfer car

- Towing tug

- Seaqx self-propelled trailer

- Seaqx electric self-propelled trailer

- Heavy load transfer car

- Heavy load rail guided cart

- 2-axle self propelled trolley

- Heavy load self propelled trolley

- Omnidirectional transfer car

- Lifting self propelled trolley

- Flatbed self-propelled trolley

- Battery-powered self-propelled trailer

- Modular self-propelled trailer

- 2-wheel tug

- Assembly automated guided vehicle

- 6-axle self-propelled trailer

- Radio-controlled tug

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.