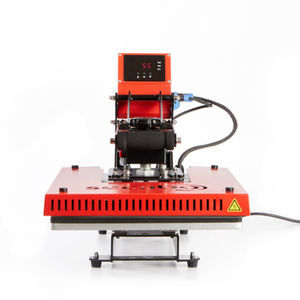

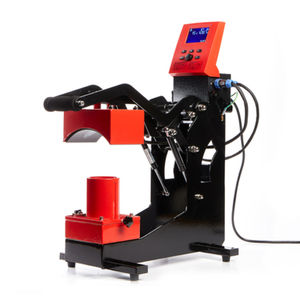

Pneumatic press Secabo TPD12heat transferdoubleautomatic

Add to favorites

Compare this product

Characteristics

- Operation

- pneumatic

- Function

- heat transfer

- Structure

- double

- Control

- automatic

- Other characteristics

- transfer

- Weight

782 kg, 931 kg

(1,724 lb, 2,053 lb)

Description

The Secabo TPD12 is an outstanding production machine for large-scale productions in the field of sublimation textile finishing and other transfer technologies up to a size of 100cm x 120cm. The pneumatic double plate heat press features a heating capacity of 9.0 kW and designed to provide a maximum pressure of 4 bars, which corresponds to the 140g/cm2 or 1,700kg when using the XXL heat plate. This means, that the TPD12 is perfectly equipped for large runs of high quality large format transfers. The two base plates are superimposed on an electric linear system specially designed to retract one base plate into the heat press, while simultaneously exposing the other base plate. This feature serves to increase efficiency by enabling operators to remove a finished transfer object and/or prepare the next transfer object at the same time, that the other base plate is inside the transfer area within the TPD12's case. The user can choose different modes of operation, namely automatic or manual. In each case, operators are offered protection from injury by a wide range of safety equipment, including emergency shutoff and two-handed operation. The TPD12 facilitates a means for profitable and efficient production of large-scale transfers in large quantities.

Features

Digital controller

Duration and temperature can easily be adjusted and monitored using the digital controller.

Variable work pressure

The work pressure is easy to adjust - in each case matching the transfer object and procedure.

Safe working

The safety and quality of this device is constantly monitored - according to German safety standards.

VIDEO

Catalogs

No catalogs are available for this product.

See all of SECABO‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.