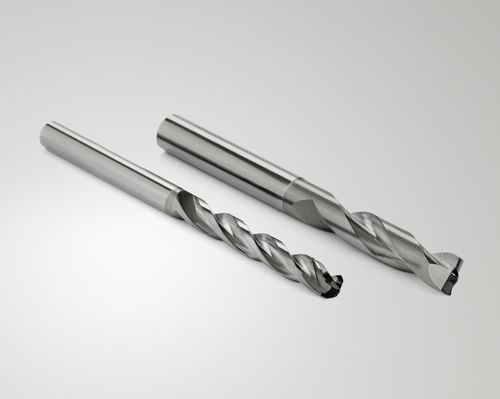

Seco offers two distinct solutions for composite drilling: diamond-coated drills and polycrystalline diamond (PCD) drills. These tools feature geometries that are optimized specifically for regular composites or stacked materials.

For drilling through plain composite materials, C1 and CX1 applies a double-angle geometry to redirect axial forces in a way that reduces uncut fibers and delamination in composite-only applications and applications with an exit in composite material.

The C2 and CX2’s flat-geometry drill point machines stacked composite materials that incorporate layers of aluminum or titanium. With a drill point angle of 180 degrees , the geometry provides efficient chip breaking and evacuation. This reduces the risk of metal chips damaging the hole when transitioning between layers of metal and composites, keeping the surface finish of the composite intact.

Both C1 and C2 are diamond-coated carbide drills featuring a Dura diamond coating that provides very good toughness and abrasive resistance to ensure long tool life. They can be used in CNC and handheld drilling machines.